What do honeycombs, spider webs, and corals have in widespread? They’re all examples of naturally occurring lattice buildings. Product of a daily, repeating sample of interlocking ‘unit cells’, lattices present distinctive capabilities as a consequence of their mixtures of energy, flexibility and floor space.

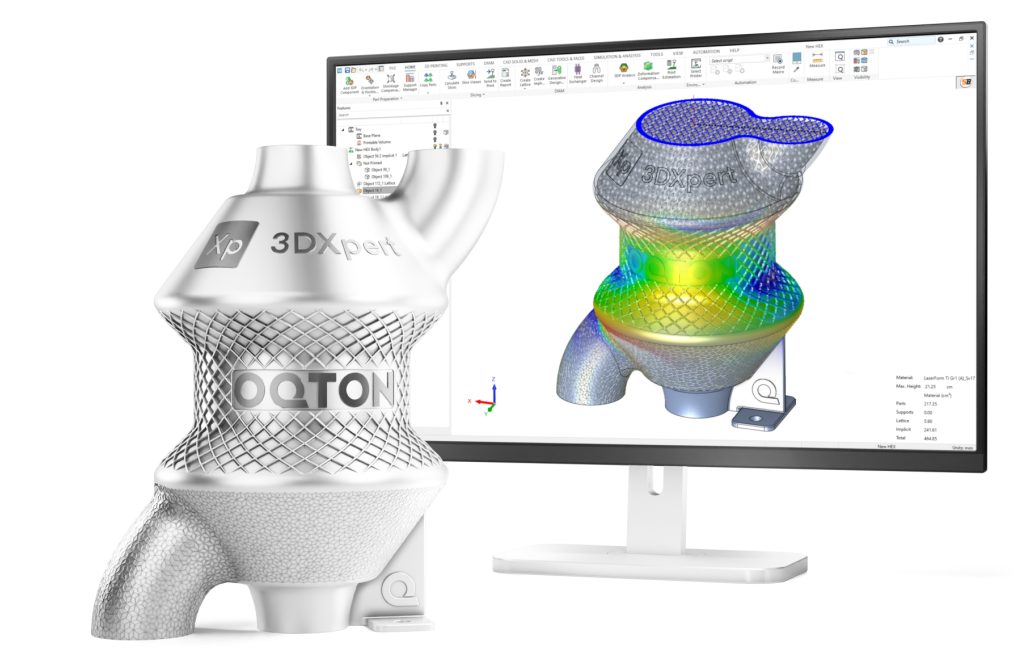

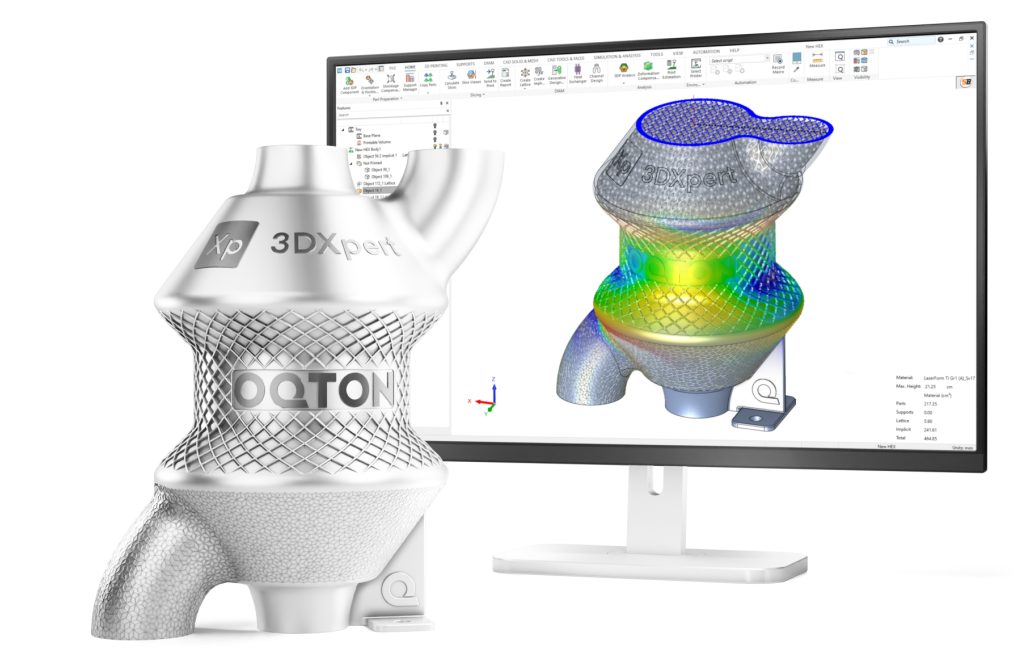

Right this moment, additive manufacturing methods and Oqton 3DXpert software program make it attainable to make use of lattices in lots of product varieties, from aerospace to athletic sneakers, to reinforce design and enhance efficiency.

Some great benefits of lattice buildings

Lattice buildings ship stunning energy and rigidity whereas utilizing much less materials than conventionally manufactured components. This easy idea ends in quite a few benefits.

The financial affect of lowering materials might be vital and even enable producers to provide the identical variety of merchandise with a decrease funding. Lighter merchandise additionally assist with gasoline effectivity.

Moreover, lattices improve floor areas. That is notably useful in purposes that use floor space to attain an environment friendly fluid, thermal or chemical interplay, resembling warmth exchangers.

Lattices additionally enable for optimizing the strength-to-weight ratio of components. Resulting from their geometry, lattices assist obtain vital energy and rigidity whereas minimizing the quantity of fabric concerned.

Total, 3D printed lattices ship nice design flexibility. Ruled by a brand new algorithm and prospects, lattices enable designers to pursue progressive, natural designs.

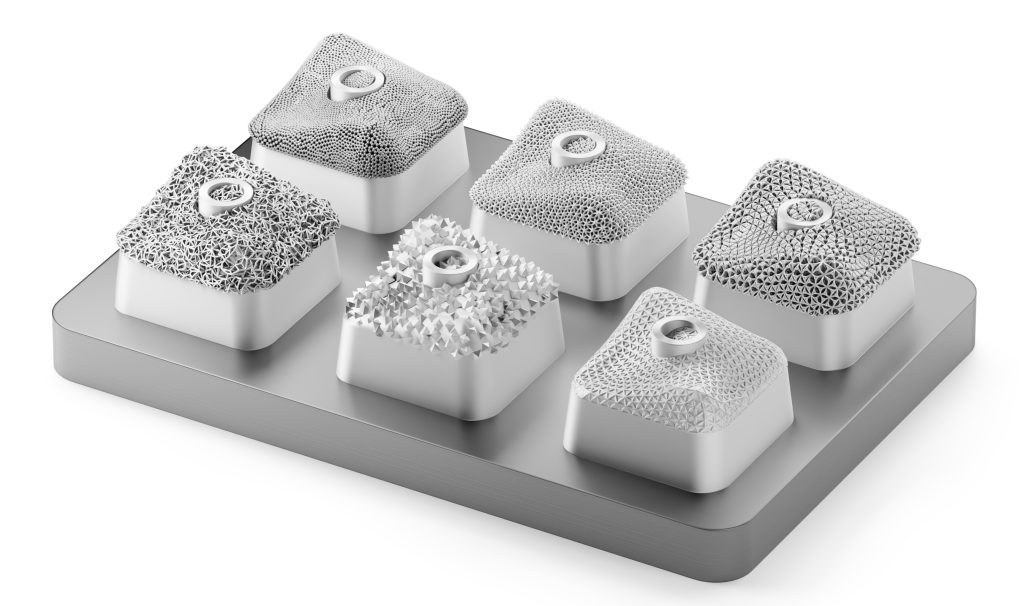

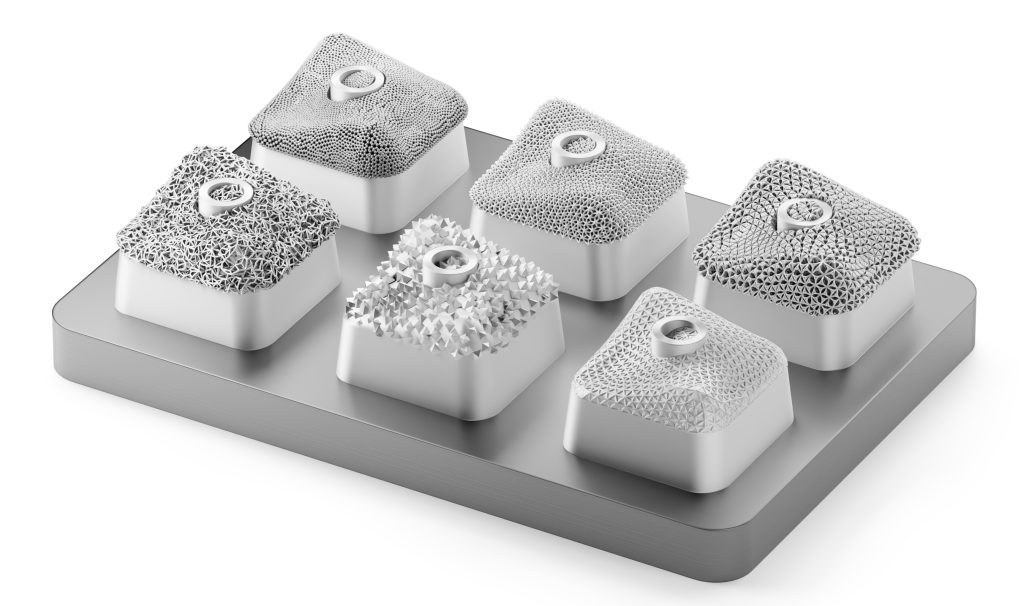

Sorts of lattice buildings

There are dozens and dozens of subtypes of lattices, however a number of the commonest are:

- Planar lattices take a 2D (or planar) association of unit cells, mostly a honeycomb, and swipe it in three dimensions.

- 3D uniform/periodic lattices might be constructed from 3D cells that tessellate a quantity. A number of examples of such cells are icosahedral, tetrahedral, and rhombic.

- Strut lattices characteristic a sequence of interconnected rods (or beams) in varied configurations. The struts could also be joined on the vertex, edge, face, or a number of factors.

- Triply periodic minimal surfaces (TPMS) depend on complicated equations that may’t be generated with standard CAD instruments. One of the crucial well-known is the gyroid.

Functions of 3D printed lattices

Lattice buildings create attention-grabbing alternatives in design and manufacturing.

Lightweighting is a well-liked utility of lattices. By including lattice buildings to a product, you may obtain a particular efficiency with the lightest attainable construction. This has massive implications for gasoline effectivity in aerospace manufacturing.

Warmth exchangers, gadgets that facilitate the method of warmth change between two fluids, also can profit vastly from lattices. Lattices are unlocking new alternatives for warmth exchanger optimization as a result of they’ve a really excessive surface-to-volume ratio that allows extraordinarily environment friendly warmth switch.

Lattice buildings are additionally nice for affect absorption. By various the density and cell sort of lattices, designers can create buildings that take up power and redirect it extra successfully than conventional foam. That is utilized in client items like trainers and bike helmets, amongst many others.

Moreover, lattice buildings are used for medical implants that promote osseointegration, or bone development, as a result of they are often 3D printed as a part of the implant.

A 3D printed spinal cage with lattice buildings. Picture through Oqton.

Overcoming challenges with 3D printed lattices

Whereas 3D printed lattice buildings ship distinctive properties, additionally they carry distinctive challenges.

Advanced lattices might be tough to 3D print as a result of the 3D fashions might be too giant for computer systems to comfortably convert into printable STL recordsdata. This may trigger slowdowns and improve the danger of knowledge loss. Because of this 3DXpert software program integrates design and print preparation, eliminating the necessity to convert the lattice to an STL file.

For osseointegration merchandise, the distribution of pores is a important issue for bone development. 3DXpert contains devoted pore distribution histograms to validate these lattices for medical merchandise in addition to instruments to assist stop protruding lattice struts that trigger tissue harm.

Creating merchandise with complicated lattice buildings also can appear intimidating to those that aren’t intimately conversant in additive manufacturing. 3DXpert’s devoted Warmth Exchanger Software contains options that may streamline the design of lattice buildings and additive manufacturing workflows.

3D printing software program for lattice buildings

The potential of lattice buildings for product design and efficiency is immense, and product designers are nonetheless exploring new makes use of.

Regardless of the utility, 3D printing software program will play a important function in making certain lattices are efficiently utilized to client items, industrial elements and medical gadgets.

Register now for AMAA 2024 to listen to insights from business specialists on additive manufacturing in aerospace, house, and protection.

Wish to assist choose the winners of the 2024 3D Printing Business Awards? Be a part of the Professional Committee at the moment.

What does the way forward for 3D printing maintain?

What near-term 3D printing tendencies have been highlighted by business specialists?

Subscribe to the 3D Printing Business e-newsletter to maintain updated with the newest 3D printing information.

You can even comply with us on Twitter, like our Fb web page, and subscribe to the 3D Printing Business Youtube channel to entry extra unique content material.

Featured picture reveals lattice buildings 3D printed with Oqton 3DXpert. Picture through Oqton.