The 3D Printing Business engineering workforce critiques the Bambu Lab X1E, a desktop 3D printer that has shaken the established order, set new requirements, and maybe divided the 3D printing group in a method not seen since MakerBot moved away from RepRap.

Essentially, the Bambu Lab X1E is an FDM 3D printer that includes enhanced community connectivity and a core-XY configuration software head. The complete bundle of velocity and reliability at an interesting value level has drawn many admirers.

Since arriving on the scene in 2020, Bambu Lab has launched a number of 3D printers, together with the X1 Carbon (September 2022), the P1P (November 2022), the P1S (August 2023), the A1 Mini (September 2023) and the X1E in October 2023.

Earlier this yr, market intelligence agency CONTEXT highlighted that Bambu Lab is driving the rising market dominance of entry-level 3D printers. Based on its This autumn 2023 report, shipments of the corporate’s desktop methods elevated by 3000% in 2023.

Nevertheless, the Bambu Lab X1E isn’t with out its critics. Considerably, detractors level to community insecurity considerations that potential customers ought to think about.

Learn on for our full report and in depth 300+ hour testing of Bambu Lab’s newest addition to the desktop 3D printer market.

Bambu Lab X1E Key Options and Advantages

The Bambu Lab X1E’s options search to deal with widespread complaints about desktop 3D printers and improve the person expertise.

The 3D printer’s quick printhead has a most print velocity of 500mm/s which, along with tuned software program facilitates the exact declaration obligatory to stop failed prints. Mixed, the printhead and software program allow 3D printing speeds that enormously cut back the time between 3D prints and enhance productiveness.

The all-new sizzling finish has a most temperature of 320°C, whereas the actively heated construct chamber tolerates as much as 60℃. These options broaden the usable materials palette and unlock a variety of purposes.

Air filtering comes from a coconut shell granulated H12, G3 air purification filter designed to get rid of poisonous fumes from supplies that emit caprolactam or styrene. When sure filaments, reminiscent of ABS and nylon, are heated throughout 3D printing, they emit ultrafine particles (UFP) and risky natural compounds (VOC). These emissions will be dangerous and embody chemical substances identified to be carcinogens, irritants, and developmental and reproductive toxins.

The X1E’s heavy-duty air filter minimizes these emissions, making it secure to make use of the X1E for extended durations.

The X1E’s AI failure detection makes use of a micro-lidar digicam. This advantages the person by decreasing each materials waste and downtime.

Safety-minded people could also be to know that the X1E now helps WiFi WPA2 Enterprise Authentication, WLAN/LAN, and Ethernet, rising connectivity safety via encrypted channels. That is perfect for individuals who want to carry out off-the-cloud printing, for instance, in a state of affairs the place design recordsdata are managed.

{Hardware} and Electronics Design and Construct High quality

The X1E has a compact, trendy, and modern look. Its gray aluminum and glass case measures 389 x 389 x 457 mm. At 16 kg, the printer is a mean weight for its measurement.

The Bambu Lab X1E 3D printer. Pictures by 3D Printing Business.

Two inflexible carbon fiber rods help the software head, making certain stability via the metal chassis, whereas the 2 belt-driven stepper motors present torque within the core-XY configuration. The warmth mattress is supported by 3 lead screws that are operated by one bigger stepper motor to manage the Z-axis gantry.

A well-insulated thick foam inside optimises the actively heated chamber temperature and offers sound absorption to keep up low ranges of noise in a piece setting.

The X1E’s person interface. Pictures by 3D Printing Business.

A full-colour 5-inch LCD touchscreen on the entrance of the system permits the customers to entry essential printing info and carry out important actions.

After rigorous testing, the X1E has undergone 300+ hours of printing and is exhibiting no indicators of wear and tear, testifying its spectacular construct high quality.

The X1E comprises numerous sensors to tell customers of upkeep checks. Scannable barcodes direct customers to the Bambu Wiki and informational movies on carry out obligatory repairs or upkeep.

X1E Setup and Calibration

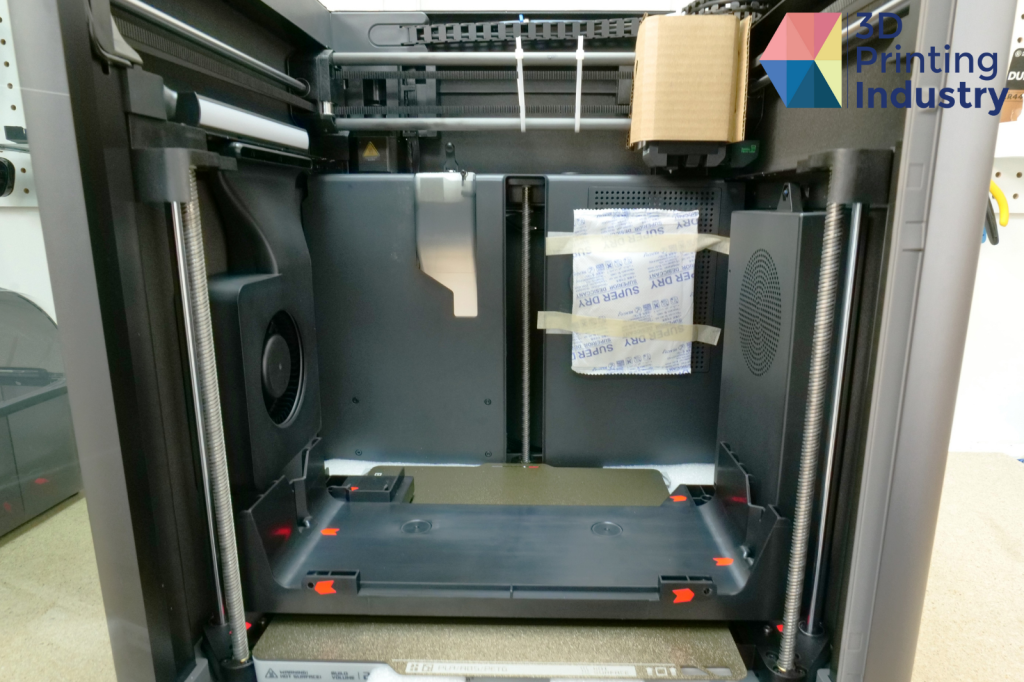

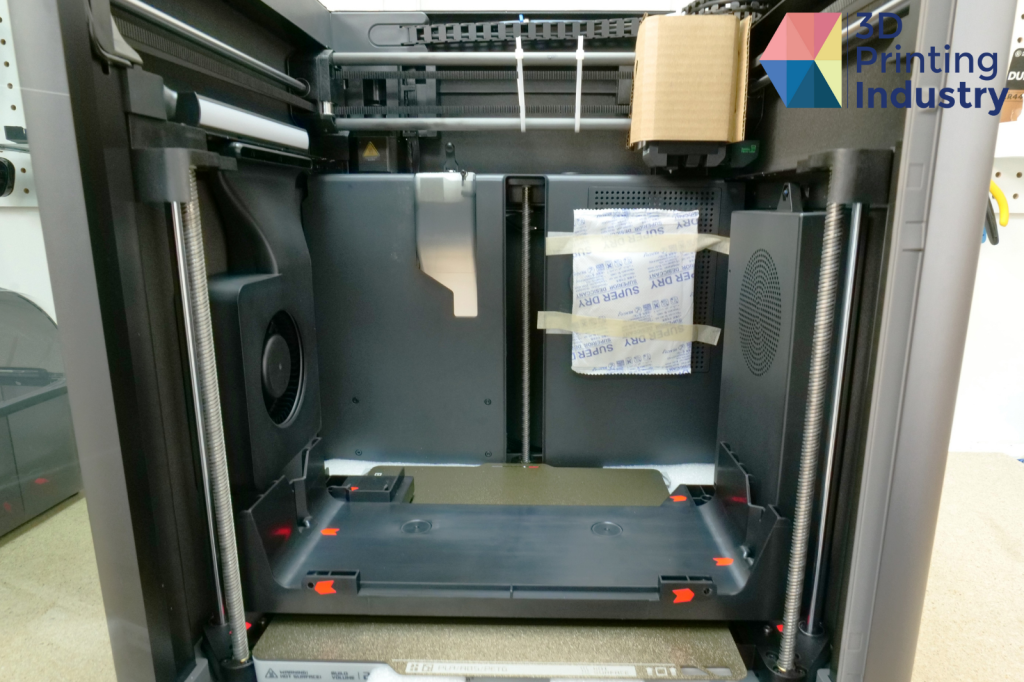

The X1E arrived effectively packaged containing applicable plastic sleeves on glass elements, with all elements being effectively secured and guarded. The unboxing course of was intuitive. Inside quarter-hour, with the usage of Allen keys and a screwdriver, the meeting was full.

Bambu Lab X1E packaging. Pictures by 3D Printing Business.

A full calibration was required to start 3D printing. This consisted of the next: Computerized mattress levelling, resonance frequency identification (a regular throughout FDM printers since 2021), Micro lidar calibration and motor noise degree calibration. The complete course of elapses a complete time of 25 minutes. That is the typical time taken by different desktop 3D printers just like the X1E.

Bambu Lab X1E calibration interface. Pictures by 3D Printing Business.

The Bambu micro lidar makes use of two twin crimson lasers to measure the depth to 7 µm precision of the mattress levelling. It additionally determines the movement charge of extrusion, together with first-layer scanning for failure evaluation.

Shut-up of the Bambu Lab X1E’s toolhead. Pictures by 3D Printing Business.

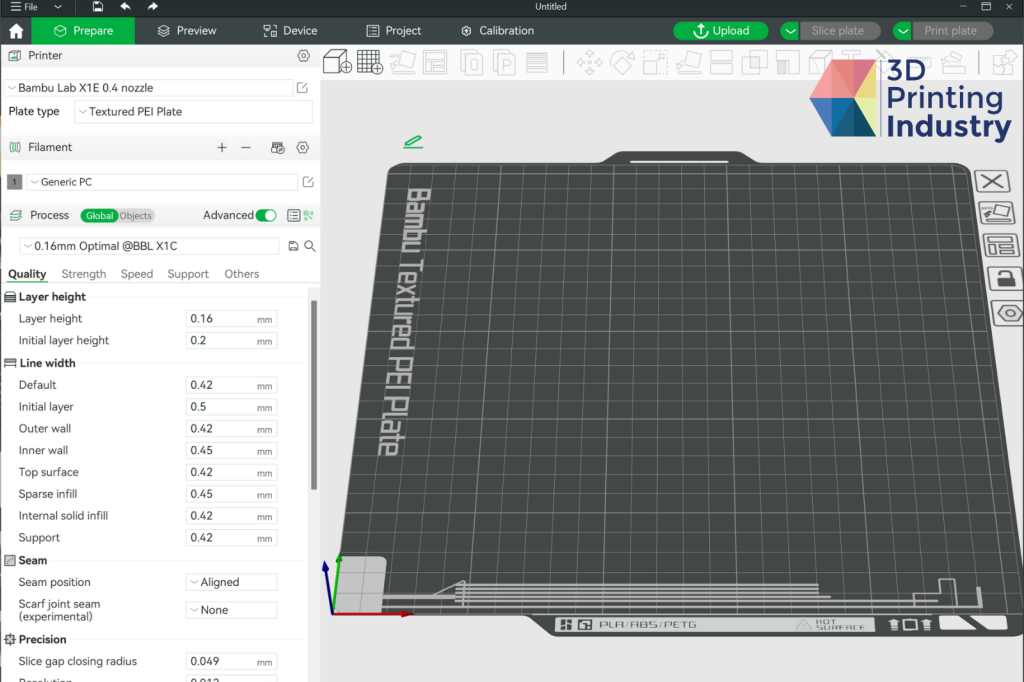

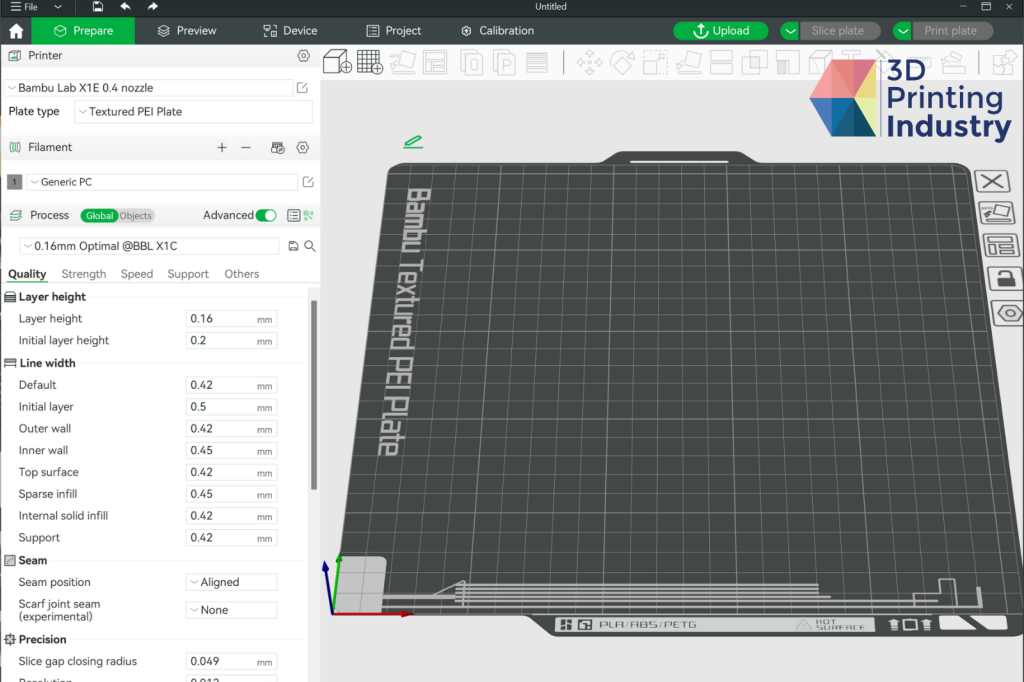

3D Printing Software program and Person Interface

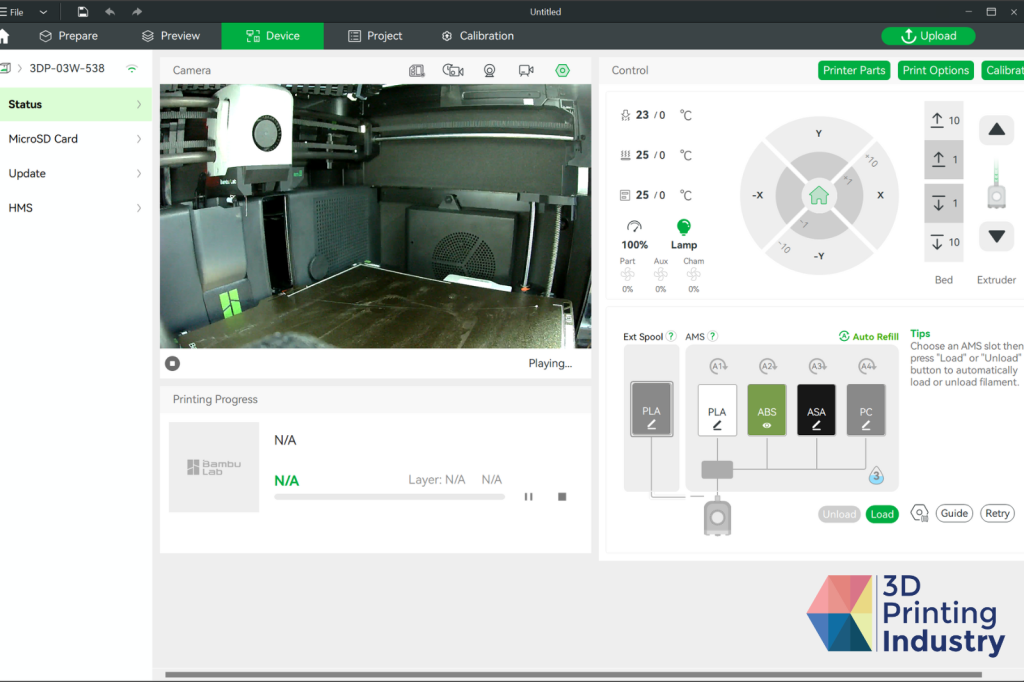

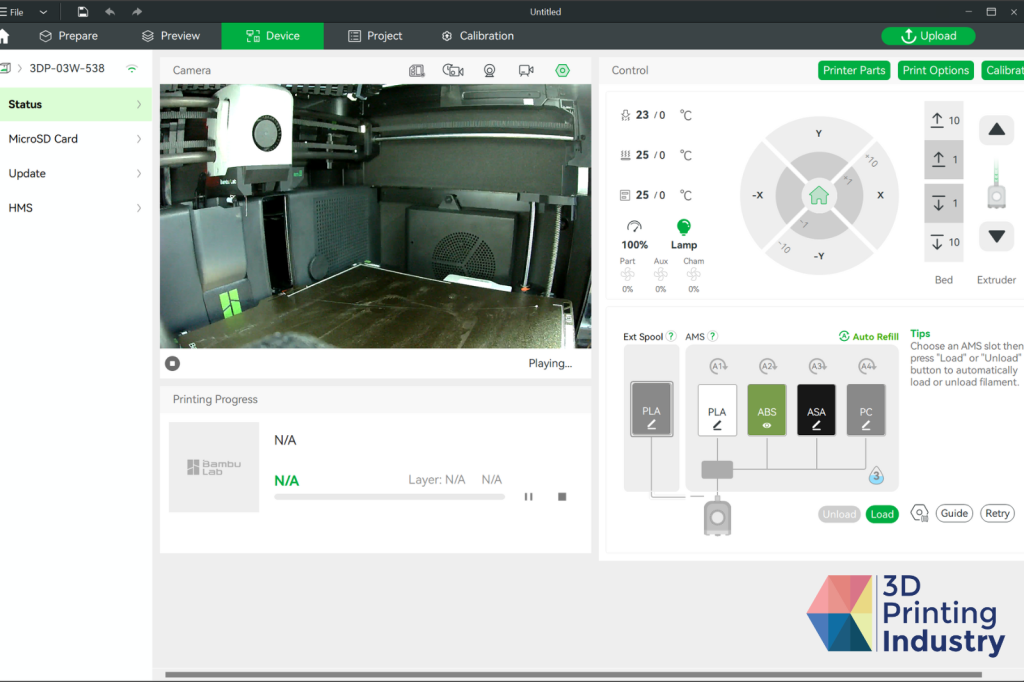

Bambu Lab affords its proprietary software program, Bambu Studio, which is suitable with all its 3D printers. Nevertheless, for the reason that X1E reads g-code, it’s not restricted to receiving g-code information by different slicers when imported utilizing a micro-SD.

The X1E’s full-colour, 5-inch touchscreen show offers customers with numerous prompts and helpful guides. Right here, all instructions reminiscent of load/unload filament, nozzle/chamber/mattress temperature, fan/print velocity and calibrations will be carried out. Entry to the construct chamber digicam can be discovered on the system tab.

The Bambu Lab X1E’s person interface instructions. Pictures by 3D Printing Business.

Bambu Studio options numerous helpful instruments not seen in different slicer software program. The multi-colour, multi-material function permits these in inventive artist industries and structure to realize a degree of design freedom not seen on different desktop methods.

This additionally permits engineering software elements to be printed with help materials, decreasing total floor defects when post-processing. The software program comprises each straightforward and knowledgeable modes, welcoming all ranges of person expertise.

The X1E’s 3D Printing Efficiency

The X1E comprises 4 firmware velocity modes which multiply the velocity of the motors and are solely amendable after beginning a print. Silent (50%), Regular (100%), Sport (124%), and Ludicrous (166%) permitting customers to quick ahead or silence 3D prints at their comfort.

In comparison with the overall desktop FDM market, the X1E excels in reliability as anomalies are hardly ever encountered. The X1E is among the few desktop 3D printers to convey actively heated chambers to the patron market. Nevertheless, extra entry-level methods at the moment are providing this function. This displays a rising pattern throughout the business towards rising affordability and accessibility of high-quality 3D printing.

Benchmarking the Bambu Lab X1E

To check the repeatability of the X1E our workforce 3D printed sq., hexagon and tube fashions 12 instances every. These had been then measured and in comparison with their authentic dimensions. Components possessing a mean deviation underneath 0.1 mm, and a regular deviation of lower than 0.05 mm are considered as profitable outcomes.

3D printed repeatability check geometries. Pictures by 3D Printing Business.

The X1E achieved excellent ends in our repeatability of the tubes, squares and hexagons. The imply distinction for all elements was 0.0573mm, with the usual deviation coming in at 0.021mm. These outcomes spotlight the spectacular consistency between accuracy and precision. As such, the X1E is appropriate for skilled customers who demand the manufacturing of repeatable high-quality elements for purposes reminiscent of jigs and meeting elements.

We subsequent performed our in-house 3DPI check. Right here, the X1E scored an excellent results of 95.85/100. That is the very best rating of all FDM 3D printers now we have examined.

This was achieved utilizing the optimum mode 0.16mm layer peak. Drawbacks had been discovered within the overhand check demonstrating points after the 70° mark. Most FDM methods produce drooping layer strains at 50°. Due to this fact, the X1E scores a effectively above common outcome.

{Our capability} assessments encompass printing 150 tubes and choosing out 16 at random to measure. Functionality is important for customers who want to 3D print giant volumes of comparable geometries. It is a crucial issue for the statistical course of management of variation. This determines the machine’s suitability to realize the required tolerances constantly.

Functionality check outcomes. Photograph and picture by 3D Printing Business.

The X1E showcased an important Cp (Course of Functionality Index) of seven.99, suggesting a extremely succesful course of output with constant values throughout the specification limits in comparison with its pure variability.

The Cpk (Minimal Course of Functionality Index) of three.887 signifies the method is precisely attaining outcomes throughout the specification limits and has a low likelihood of manufacturing defects exterior of this vary. Total, the X1E is effectively suited to mass manufacturing operations, providing prime quality and consistency.

We additionally assessed the X1E’s capacity to 3D print small and exact elements. The check piece was a small nut and bolt with tight tolerances containing a size of 28 mm. This half was 3D printed efficiently with good element and no defects within the thread, permitting it to operate as meant. Due to this fact, the X1E is appropriate for producing jigs within the automotive and aerospace sectors.

3D printed nut and bolt check. Pictures by 3D Printing Business.

Testing Bambu Lab X1E Functions

Utilizing PA6-CF we printed a lattice pulley present in RC skateboards. This was a high-quality print, with no defects identifiable or post-processing required.

3D printed lattice pulley cog. Pictures by 3D Printing Business.

Utilizing ASA, which has a glass transitioning temperature of 110℃, we had been capable of 3D print an consumption connecting pipe for a rally automobile. The consumption contained no warps or exterior defects, making it appropriate for software use within the automotive sector.

3D printed four-to-one consumption. Pictures by 3D Printing Business.

A purposeful prototype of tail gentle elements was additionally 3D printed. The lens was comprised of clear polycarbonate, permitting gentle to go via while appearing as a diffusor. ABS was used for the casing to stop any put on from environmental elements. A bracket was 3D printed in PLA to symbolize sheet steel.

3D printed tail gentle prototype. Pictures by 3D Printing Business.

Utilizing PAHT-CF, we subsequent 3D printed a drone body. This required the usage of Bambu Labs help materials. We encountered some points right here. Fortuitously, the client help workforce had been quick to reply, sometimes taking between 24 to 48 hours to offer useful hyperlinks to info and tutorials. Though it was not really easy to take away the help materials, utilizing the suitable instruments and persistence we had been profitable.

3D printed drone body. Pictures by 3D Printing Business.

One of the crucial intriguing options of hobbyists within the FDM market is the multi-colour 3D printing software selectable in Bambu Studio. The Computerized Materials System (AMS) permits customers to retailer 4 spools in its compartment. This could learn the RFID chip and routinely load the filament into the software head.

Our 3D printed firm logos and Hue Forge paintings reveal how well-suited this software is to the humanities and crafts market, producing multi-colour elements in single 3D print jobs.

We additionally produced a high-quality anatomic mannequin of a coronary heart appropriate for instructional and demonstration functions. The bio-medical business may gain advantage from the X1E for evaluating life-size 3D-printed anatomical fashions for orthopaedic oncology present in CT or MRI imaging. This permits medical practitioners to review one of the best course of for surgical procedures.

Multi-coloured 3D prints. Pictures by 3D Printing Business.

Bambu Lab Faces Information Insecurity Accusations

Based on some sources, Bambu Lab log recordsdata transferred to the cloud include mental property reminiscent of 3mf recordsdata and g-code. This seems to be a problem encountered with the earlier firmware which lacked safety protocols, making it susceptible to exterior interception which will be decrypted.

Since Bambu Studio and Bambu gadgets rely closely on their cloud providers, information breaches or unauthorized entry may trigger immense disruptions or leaks of proprietary designs.

The information collected by Bambu Lab gadgets consists of video streams and detailed print info, that are picked up by the onboard digicam and micro-lidar. These information may probably be accessed if the system is breached. It is a main concern for the protection sector, which handles extremely delicate information.

What’s extra, in 2023 all Bambu Lab 3D printers related to the cloud and spontaneously started 3D printing, damaging many gadgets. This was reportedly attributable to a glitch within the cloud service following a system reset by Bambu, inflicting 3D printers to re-print the final print job.

With stories of decrypted log recordsdata containing mental property being collected by the Bambu Cloud, Bambu has devoted the X1E to making sure community and person safety.

The 3D printer’s new ethernet port permits the X1E to function with out connecting to the cloud. The X1E additionally affords WPA2 enterprise-authenticated connectivity for safe community use and offline printing capabilities, making it well-suited to these 3D printing underneath NDA.

The X1E: A Worth for Cash Desktop 3D Printer

The X1E is just bought by resellers and is listed at £1915 – £2088 excluding VAT. The Computerized Materials System (AMS) is included on this value.

That is virtually double the worth of its predecessor, the X1C, which prices £969. The Creality K2 is a direct competitor towards the X1E. It’s priced at simply £1190 and affords comparable options, besides enhanced connectivity and a heavy-duty air filter. The Ultimaker S5 is one other contender when it comes to {hardware}. Nevertheless, this method options a way more costly value level of £10,000.

Total, we consider the X1E is a wonderful value-for-money 3D printer. It affords enticing options to allow high-quality 3D printing and is suitable with a variety of supplies appropriate for numerous purposes.

Clients can count on to spend between £2300 and £2600 for the X1E when together with consumables reminiscent of desiccants, supplies and construct plates.

The Bambu Lab X1E: A New Normal within the Desktop 3D Printer Market

The X1E excelled in all our dimensional assessments, attaining excellent outcomes. Designed for the skilled market. The 3D printer represents a big development in desktop 3D printing know-how, integrating high-speed printing capabilities with spectacular construct high quality.

The improved hotend and actively heated construct chamber enormously will increase the flexibility of supplies. As such, the X1E is effectively suited to a wider vary {of professional} use purposes throughout many sectors.

Though Bambu Lab has stepped up the cloud service safety measures by introducing further safety protocols, information safety ought to nonetheless be thought of by potential prospects. Customers also needs to carry out month-to-month upkeep checks on the X1E to keep away from downtime and inconvenience. This may be completed by greasing lead screws, clearing grime and taking warning when eradicating the nozzle to keep away from injury to wires.

Regardless of its quite a few strengths, the X1E isn’t with out drawbacks. Nozzle clogs had been typically encountered however had been simply rectified due to the magnetic software head cowl and the 2 screws which maintain the nozzle in place. Disassembly of elements is fast and straightforward to carry out with minimal effort. Mattress adhesion issues had been additionally encountered however rectified utilizing the glue stick supplied within the equipment field.

These slight points are outweighed by the 3D printer’s quite a few advantages, together with glorious print high quality, velocity, and a complete help ecosystem.

Tons of help is supplied in Bambu Wiki, which makes use of a forum-type format the place the group and consultants can remark and reply to posted issues. All consumables or spare elements will be discovered within the Bambu lab retailer.

In abstract, the Bambu Lab X1E is a extremely succesful and dependable 3D printer that delivers distinctive efficiency and person expertise. This makes it a worthy funding for each hobbyists and professionals in want of exact and constant 3D printing.

Technical Specs of the Bambu Lab X1E

| 3D Printing Know-how | FDM (Fused Deposition Modeling) |

| Construct Quantity | 256 x 256 x 256 mm |

| 3D Printer Dimensions | 389 x 389 x 457 mm³ |

| Person Interface | Contact display screen 5-inch |

| Most 3D Print Pace | 500 mm/s |

| 3D Print Acceleration | 20 m/s² |

| Most Stream Fee | 32 mm3/s |

| Most Nozzle Temperature | 320℃ |

| Heated Construct Plate Temperature | 110℃@220V, 120℃@110V |

| Heated Construct Chamber | Max 60℃ |

| Pre-filter grade | G3 |

| HEPA filter grade | H12 |

| Activated Carbon Filter sort | Coconut Shell Granulated |

| Marketed Filament Compatibility | PLA, PETG, TPU, PVA, BVOH: Optimum ABS, ASA, PC, PA, PET: Superior Carbon/Glass Fiber Strengthened PLA, PETG, PA, PET, PC, ABS, ASA: Superior PPA-CF/GF, PPS, PPS-CF/GF |

| Nozzle and Extruder Gear Materials | Hardened metal |

| Nozzle Diameter | 0.4 mm (Included)0.2mm, 0.6mm, 0.8mm |

| Filament Diameter | 1.75 mm |

| Extruder Amount | 1 |

| Filament Cutter | Sure |

| Hotend | All Metallic Hotend |

| Internet weight | 16kg |

| Slicer Compatibility | Bambu Studio |

| Connectivity | WiFi, Ethernet RJ45, WPA2 |

| File Output | .gcode |

Need to assist choose the winners of the 2024 3D Printing Business Awards? Be part of the Knowledgeable Committee at the moment.

What does the way forward for 3D printing maintain?

What near-term 3D printing developments have been highlighted by business consultants?

Subscribe to the 3D Printing Business e-newsletter to maintain updated with the most recent 3D printing information.

You may also observe us on Twitter, like our Fb web page, and subscribe to the 3D Printing Business Youtube channel to entry extra unique content material.

Featured picture reveals the Bambu Lab X1E. Photograph by 3D Printing Business.