Once we consider area exploration, the main target typically gravitates towards large rockets, refined spacecrafts, and the fascinating photos they ship again to Earth. Nevertheless, the unsung heroes in these endeavors are the important parts guaranteeing that each a part of these complicated programs communicates successfully. One of the vital important parts enabling this communication is connectors.

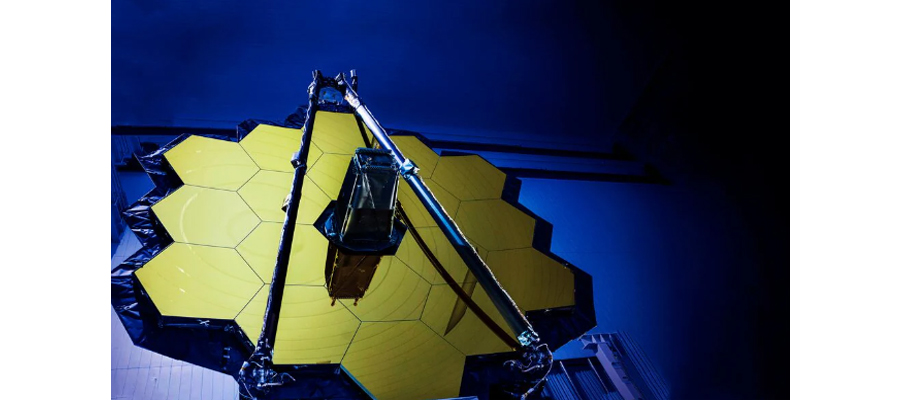

From the Artemis program’s monumental lunar missions to the revolutionary insights of the James Webb Area Telescope, the success of those missions hinges not simply on the large-scale engineering feats but additionally on the reliability and efficiency of connectors. These ubiquitous parts face the intense circumstances of area and are pivotal in each step, from the pains of launch to the cruel surroundings of outer area.

Area Exploration Ascending

Area exploration, each by authorities organizations and business ventures, may be very a lot within the information. One of the vital intensive applications in current area historical past is the Artemis program, which can see people return to the Moon. The Area Launch System (SLS) accomplished its first profitable check mission in December of 2022 and kinds the most important element of this system. Nevertheless, the most recent steps in our return to the Moon usually are not the one thrilling initiatives in area.

Whereas these high-profile occasions seize the general public’s creativeness, they characterize only a small a part of the image. Exploration and exploitation of area are on a regular basis actions. Greater than 200 area launches had been made in 2023 alone, carrying science missions and satellites into orbit and past.

The Excessive Circumstances of Area

Regardless that spaceflight has grow to be extra widespread, the circumstances through which these programs should carry out are not like some other. Area represents probably the one most demanding surroundings identified to engineering. Any tools utilized in spaceflight is uncovered to a variety of extremes, from excessive and low temperatures and harsh radiation to the severities of the launch course of and the vacuum of area.

The shortage of ambiance in area is extremely unforgiving. On Earth, our ambiance is a protecting blanket that gives stress, thermal insulation, and security from dangerous radiation. This safety is stripped away in area, exposing tools to potential harm.

With out the ambiance to guard it, an object in area receives the complete power of the solar’s radiation. When tools is bombarded by direct daylight, its temperature can rapidly grow to be dangerously excessive. In distinction, the elements of a spacecraft that stay in shadow are very chilly. These temperature extremes, should be thought-about when choosing the supplies to make use of aboard area autos. Different radiation sources, together with galactic cosmic rays, are extremely ionizing and may hurt delicate devices or refined digital circuits.

Selecting the Proper Supplies for Spaceflight

The shortage of atmospheric stress additionally causes supplies to behave in distinctive methods. Parts employed for spaceflight can face an array of challenges that have an effect on efficiency. Outgassing is when a gasoline trapped inside one other materials is launched. This can be a widespread drawback when plastic is uncovered to a vacuum throughout spaceflight, however it’s not restricted to plastics alone. Some metals, together with zinc and cadmium, are additionally vulnerable to sublimation in vacuum circumstances, each of that are generally utilized in standard tools design.

In each instances, the gasoline that’s launched may cause harm. It could condense onto chilly surfaces such because the optics and sensors of scientific tools, which may degrade and even negate their effectiveness and put the complete mission in danger. NASA and the European Area Company (ESA) have really useful quantity ranges of outgassing for supplies used of their area functions. These suggestions play a key function in choosing parts for spaceflight.

Parts additionally should be mechanically strong, as launching satellites, probes, and spacecrafts into orbit exposes them to acceleration and vibration that may trigger harm that may be undiscovered for months or years. As such, plastic parts should be manufactured utilizing supplies that exhibit excessive stability, even in vacuum circumstances.

To offer options for these demanding circumstances, connectors designed for spaceflight should be amongst probably the most superior within the business. Manufactured to stringent requirements and examined to show their efficiency even within the vacuum of area, they’re the very definition of high-reliability connectors.

Engineered for Most Endurance

If the spaceflight surroundings is just not difficult sufficient, there’s one further side that contributes to the difficulties of designing for spaceflight: endurance. Whether or not meant for business or scientific functions, area missions can final for years. If a chunk of kit fails, having access to repair the issue is actually inconceivable. In these circumstances, designers and engineers rely on the reliability of every element that makes up the tools, irrespective of how small.

Endurance additionally performs a vital function in energy planning. A protracted-range probe operates on a stringent energy price range, and any element that introduces undesirable electrical resistance will threat jeopardizing the mission. {The electrical} terminals of connectors designed for area functions are created from high-performance supplies and coated with a thick layer of gold, guaranteeing minimal electrical resistance to cut back energy loss.

Contacts with low electrical resistance present further advantages past energy planning. The devices on area probes take extremely exact measurements, and the currents generated by these sensors will be extraordinarily small. For these tiny currents, low contact resistance is essential to maximise the probability of detecting important indicators.

With endurance in thoughts, connectors designed for spaceflight functions use supplies that present the very best efficiency by decreasing interference. Producers should be sure that the magnetic signature of any element is minimized to stop interference with precision scientific experiments. The connector shell additionally protects towards electromagnetic interference (EMI). Autos that should traverse the vacuum of area are unprotected towards photo voltaic radiation, which may intervene with scientific observations and harm delicate devices. That is one more reason why the shells of spaceflight connectors are gold-plated, which supplies the best potential safety towards EMI in these circumstances.

Mission-Essential Connector Engineering

Connectors play an often-overlooked function in spaceflight functions. Area autos are usually manufactured from sub-assemblies, that are introduced collectively earlier than launch. Connectors present the very important interface between every system through the intensive testing regime earlier than launch and the demanding circumstances in area. Spaceflight connectors are designed in keeping with a number of the highest requirements within the interconnection business and, in consequence, characterize a number of the most succesful merchandise out there at this time.