Throughout eutectic solidification, a mix of two or extra solids self-assemble, forming composite microstructures starting from ordered layers to intricate maze-like patterns that underlie properties like tensile energy or ductility.

Up so far, researchers haven’t understood what circumstances drive eutectics to type sure patterns, which is important for designing reproducible next-generation eutectic composites.

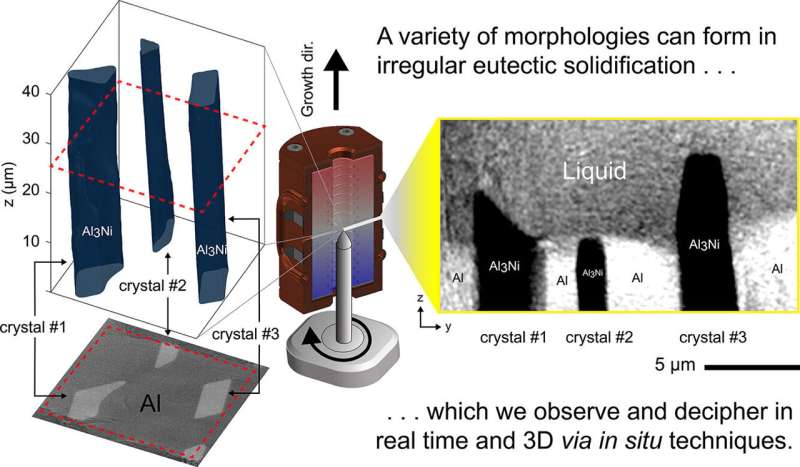

Capturing real-time solidification of an aluminum-nickel eutectic alloy (Al-Al3Ni) in nanometer decision revealed that growing the solidification velocity shifts microstructure from irregular and faceted to common and rounded, based on a research led by College of Michigan researchers just lately printed in Acta Materialia.

Leveraging this new understanding of eutectic formation will assist tune microstructure for the fabric class utilized in high-temperature elements in generators or reactors.

“I’ve at all times been captivated by patterns in nature—like snowflakes, the place no two are ever an identical.

“This fascination with how such seemingly easy processes can provide rise to endlessly wealthy, complicated, and distinctive constructions drives me to discover the underlying rules behind them,” stated Ashwin Shahani, an affiliate professor of supplies science and engineering and chemical engineering at U-M and senior creator of the research.

“In supplies science, the identical type of surprise applies: how do small adjustments in circumstances result in dramatically completely different microstructures?”

To higher perceive how eutectic microstructures type, the analysis workforce designed a brand new in-situ furnace on the synchrotron beamline for directional solidification—a way the place the crystal progress from the liquid to strong section is oriented in a particular course. The equipment permits exact management over the solidification processing area, enabling detailed research of sample formation throughout eutectic solidification.

To correlate the nanoscale observations with microscale phenomena, the researchers mixed two visualization methods. Optical microscopy captured solidification over massive space- and time-scales whereas synchrotron transmission X-ray microscopy supplied nanoscale insights. The latter was carried out on the full-field X-ray imaging beamline 18-ID at Brookhaven Nationwide Laboratory’s Nationwide Synchrotron Mild Supply II.

With this, they immediately noticed the interplay between the liquid, aluminum (Al) and nickel aluminide (Al3Ni) crystals throughout solidification beneath completely different circumstances. The expansion price of Al3Ni in comparison with Al—known as the diploma of coupling—decided the form of the strong microstructures left behind.

For instance, when solidifying at decrease velocities, the main ideas of the Al3Ni develop forward of Al, inflicting irregular, faceted progress. At excessive solidification velocities, Al3Ni and Al develop on the identical price, leading to rounded, common progress.

In a casting, solidification velocity relies on a number of components, together with the thermal conductivity of the soften and the speed of warmth extraction.

“Our first-of-its-kind experiments and real-time observations assist to clarify the good range of patterns produced by the solidification of eutectics containing stiff, intermetallic phases. These insights are important to tell and validate simulations of supplies synthesis,” stated Paul Chao, a doctoral graduate of supplies science and engineering at U-M, who spent a full 12 months in 2022 as a resident researcher embedded on the synchrotron beamline, and first creator of the research.

“Our experiments serve for instance of how glorious mentorship on the College of Michigan, partnership with Brookhaven Nationwide Laboratory, and worldwide collaboration are important to cutting-edge analysis that may resolve basic scientific enigmas.”

This discovering is of broad relevance to a large spectrum of eutectic techniques together with these which are metallic, semi-metallic and natural.

“Manipulating these patterns is greater than only a technical pursuit—it’s a method to unravel basic rules and apply them in significant methods, from enhancing the energy of supplies to pioneering new approaches in supplies design,” stated Shahani.

Extra data:

Paul Chao et al, From irregular to common eutectic progress within the Al-Al3Ni system: In situ observations throughout directional solidification, Acta Materialia (2024). DOI: 10.1016/j.actamat.2024.120314. On arXiv: DOI: 10.48550/arxiv.2408.14346

Supplied by

College of Michigan School of Engineering

Quotation:

Unraveling the elemental rules of eutectic solidification with real-time, nanoscale imaging (2024, September 9)

retrieved 9 September 2024

from https://phys.org/information/2024-09-unraveling-fundamental-principles-eutectic-solidification.html

This doc is topic to copyright. Other than any honest dealing for the aim of personal research or analysis, no

half could also be reproduced with out the written permission. The content material is supplied for data functions solely.