Vallourec, a number one French tube producer, has efficiently used wire arc additive manufacturing to create a downhole part that meets stringent American Petroleum Institute requirements. The corporate’s dedication to WAAM alerts a promising shift in the usage of 3D printing applied sciences for the oil and gasoline trade.

Vallourec, which generates $3.4 billion in income and employs 17,000 folks, has lengthy been acknowledged for its experience in seamless metal tubes for sectors comparable to vitality and automotive. In a LinkedIn put up, Vallourec’s Head of Additive Manufacturing, Olivier Tartar, highlighted the agency’s newest achievement: producing a downhole part utilizing WAAM know-how, which handed the demanding API 5C5:2017 CAL-IV normal for tubing and casing connections.

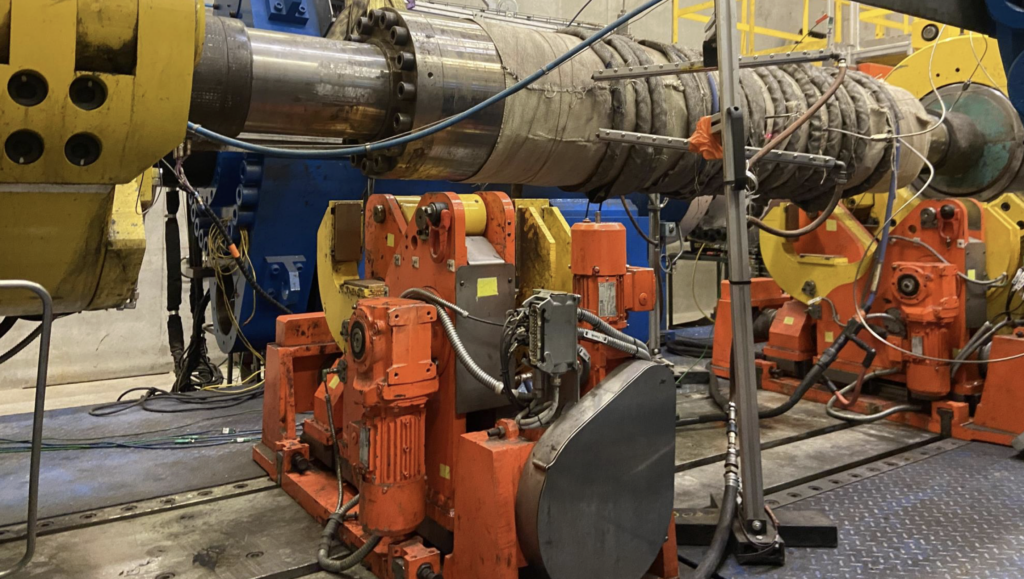

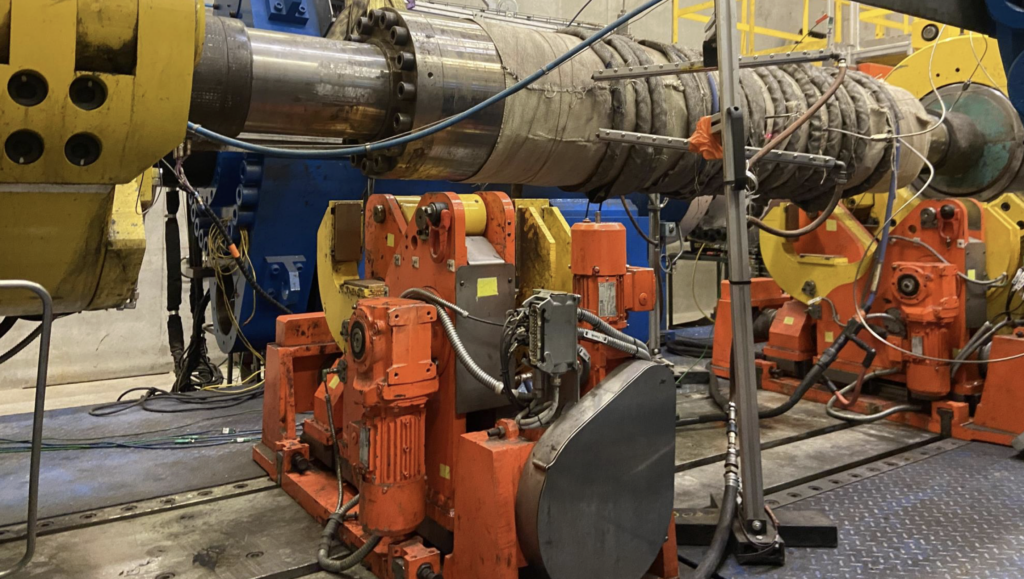

Regardless of preliminary hesitations inside the trade, WAAM is gaining renewed consideration for its velocity and cost-effectiveness, notably within the vitality sector. Vallourec’s deal with refining this know-how entails integrating robotic arms and ultrasonic inspections in manufacturing cells, permitting the manufacture of enormous components, as much as 2 meters excessive and 1 meter in diameter. This functionality is vital for industries that demand fast, high-quality manufacturing.

Improvements in WAAM Expertise

WAAM know-how has skilled ups and downs over time. Whereas it was initially embraced, its use dwindled on account of challenges like post-processing and management limitations. Nevertheless, Vallourec has refined the method by integrating robotic techniques and superior inspection instruments, enabling the creation of high-performance parts.

For instance, Vallourec efficiently produced a lifting plug for an oil platform within the Timor Sea, able to withstanding a 100-ton load. This half was made at a fraction of the time and price in comparison with the standard cast different. Such developments showcase the potential of WAAM to deal with pressing trade wants, comparable to decreasing downtime in oil and gasoline exploration and manufacturing.

Assembly API Requirements with 3D-Printed Elements

The current success of Vallourec’s WAAM-printed downhole part, which handed the rigorous API 5C5:2017 CAL-IV normal, marks a significant milestone. The API normal ensures tubing and casing connections can endure high-pressure, high-temperature circumstances generally encountered in oil and gasoline operations. Vallourec examined a 9 5/8” cross-over tube underneath excessive circumstances, making use of each pressure and compression, and subjected it to inside and exterior pressures of as much as 1,000 bars and 600 bars, respectively.

Olivier Tartar emphasised that the success of this part demonstrates WAAM’s competitiveness with standard manufacturing strategies, together with casting and forging. As Vallourec continues to refine the know-how, the potential for widespread adoption in vital sectors turns into extra obvious.

Supply: 3dprint.com