Penn State researchers have developed a 3D printed, comfortable, and stretchable materials that self-assembles. This materials is designed to advance comfortable robotics, skin-integrated electronics, and biomedical gadgets by matching the properties of tissues and organs whereas offering excessive conductivity.

Conventional liquid metal-based conductors require complicated secondary activation processes, which might trigger gadget failure because of leakage. The analysis staff, led by Tao Zhou, has utilized a brand new methodology combining liquid metallic, the conductive polymer PEDOT, and hydrophilic polyurethane.

This composition permits the fabric to self-assemble through the printing and heating course of. The liquid metallic particles kind a conductive pathway on the fabric’s backside floor whereas oxidizing to create an insulated high layer. This dual-layer construction ensures correct knowledge assortment by stopping sign leakage.

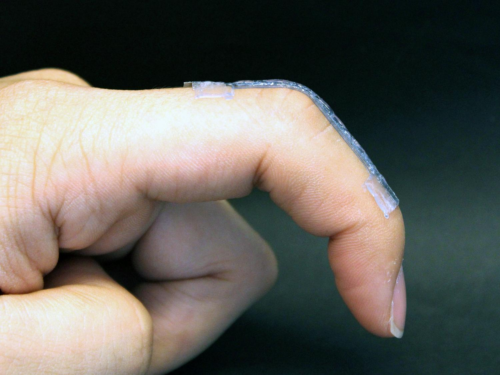

The brand new materials doesn’t require secondary activation to attain conductivity, simplifying the fabrication of wearable gadgets. This innovation in supplies science permits the creation of sensors that may be worn on the physique, reminiscent of these for muscle exercise recordings and pressure sensing. The researchers proceed to discover purposes, significantly in assistive expertise for individuals with disabilities.

This work, revealed in Superior Supplies, was supported by varied Penn State departments and collaborative applications. You’ll be able to learn the complete analysis paper at this hyperlink.