Forward of the inaugural on-line occasion Additive Manufacturing Benefit: Aerospace, House, and Protection 3D Printing Business is working a sequence of articles centered on the appliance of 3D printing in these important sectors. Register now for AMAA 2024 on July sixteenth to listen to extra insights from sector leaders.

Throughout an interview at RAPID + TCT 2024, Velo3D’s CEO Brad Kreger outlined how the corporate has tailored to the altering wants of the aerospace, area and protection industries.

Appointed as CEO of the metallic 3D printer producer in February 2024, Kreger has witnessed the protection sector remodel over the previous six months. This has been characterised by elevated 3D printer demand and an urgency to speed up adoption, pushed by international battle and growing provide chain insecurities.

He believes the “3D printing trade is in a state of recalibration,” and that additive manufacturing is not seen because the “panacea that solves all issues.”

The Velo3D CEO rationally argues 3D printing provides vital worth for low-volume, high-mix manufacturing of large-scale, mission-ready elements. Right here, Velo3D’s know-how can cut back provide chain timelines from months to weeks, enabling flexibility and price efficiencies for producers.

Turning to overcome limitations in aerospace 3D printing, Kreger emphasised the necessity to advance high quality assurance capabilities and regulatory requirements. He believes rising 3D printing adoption in army purposes will improve confidence inside the civilian aviation and aerospace sectors.

Discussing the profitability challenges going through 3D printer tools producers, he highlighted the significance of producing peripheral income streams. For Velo3D, this consists of its service help, materials improvement, and Circulate Developer software program choices.

Learn all of the information from RAPID + TCT 2024

3D printing for aerospace, area, and protection

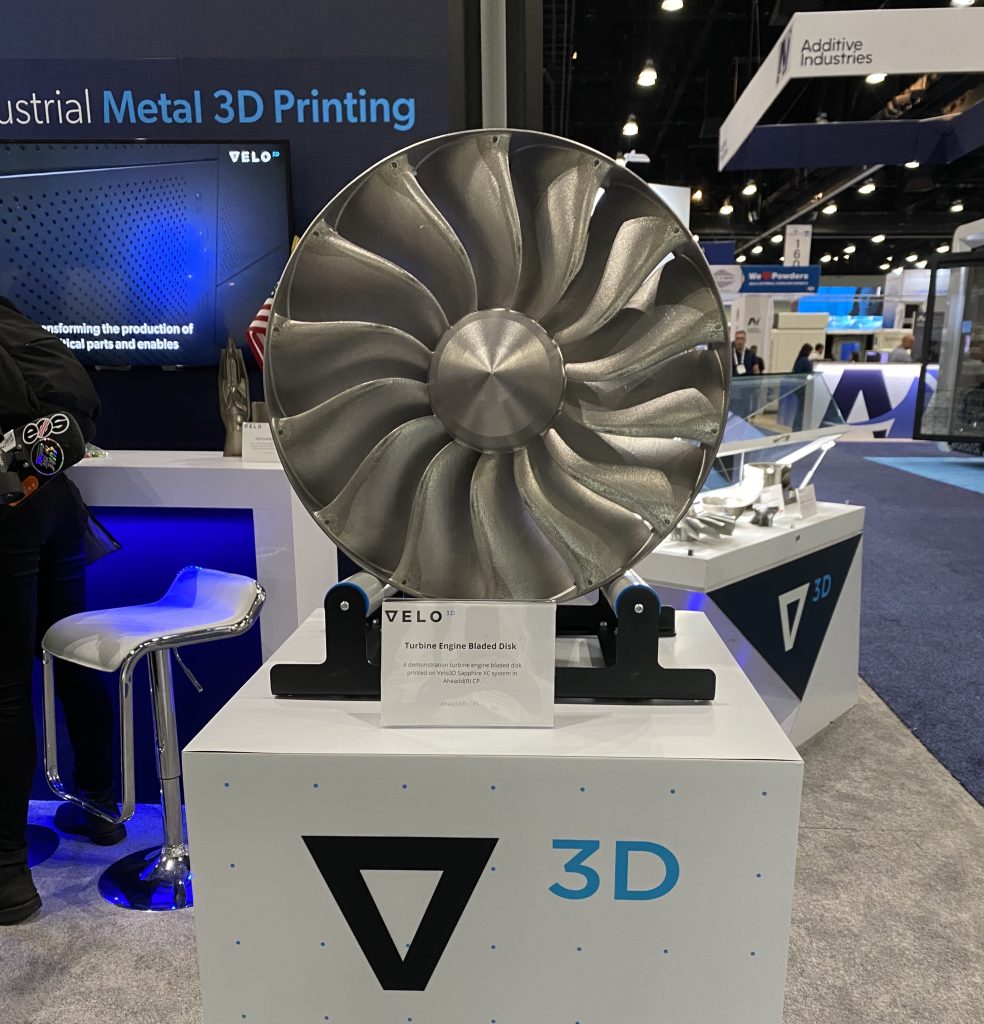

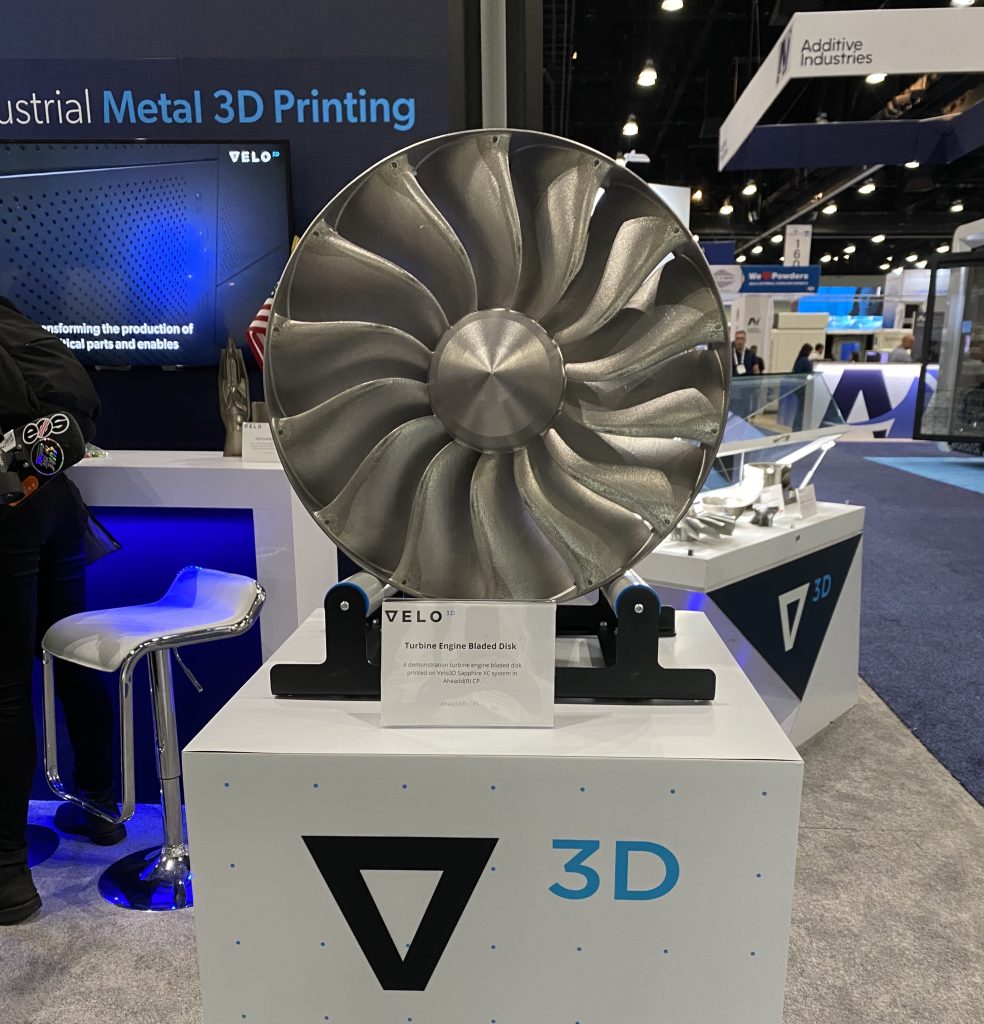

The aerospace, area, and protection industries are “strongholds” for Velo3D. The corporate provides laser powder mattress fusion (LPBF) 3D printers optimized for large-format metallic elements. For instance, its Sapphire XC system was just lately chosen to help the U.S. Naval Nuclear Propulsion Program.

Kreger acknowledged that calculating the full addressable marketplace for aerospace, area, and protection is difficult as a consequence of trade fluidity. “If I have been to reply that query six months in the past, it’d be a way more conservative reply to what I would offer now,” he defined.

The Velo3D CEO acknowledged that it’s measured in billions of {dollars}, pointing to the US Protection price range handed in March 2024. This allotted over $800 billion to protection spending, a “very giant portion” of which was earmarked for additive manufacturing.

When requested how the corporate stands out in these high-value markets, Kreger highlighted Velo3D’s non-contact recoater blade know-how. Most LPBF 3D printers function recoater blades that unfold the metallic powder over the construct plate by way of bodily contact. This could create defects in elements and restrict design complexity.

The corporate’s recoater blades are suspended above the powder mattress, utilizing managed air stream to unfold materials extra evenly. This permits complicated 3D printed geometries and angles that “our opponents will not be in a position to obtain.”

One other essential differentiator for Velo3D is reproducibility. “You possibly can qualify a component on our 3D printers, after which reproduce that very same half on some other system,” he defined.

This unlocks the potential for geographically distributed manufacturing. For example, SpaceX presently possesses 25 of the corporate’s 3D printers. When the US-based non-public area firm experiences a surge in demand, it leverages Velo3D’s community of contract producers to fulfill manufacturing necessities.

How scalable is additive manufacturing?

Kreger sees “large potential” for scaling additive manufacturing, noting that the corporate’s prospects goal manufacturing purposes. This demand is especially prevalent amongst protection companies that need to transfer from casting to additive manufacturing. In accordance with the CEO, many of those firms have reportedly recognized the necessity for ten to fifteen 3D printers to supplant present provide chains, giving Velo3D “good visibility to proceed scaling.”

Kreger defined that 3D printing manufacturing runs are extremely variable and decided by the appliance. Velo3D’s know-how is especially used for small runs of large-scale metallic elements. With 3D print occasions of as much as ten days, prospects usually fabricate tons of of those elements a 12 months.

The time financial savings supplied by the corporate’s 3D printers are “transformative,” Kreger acknowledged. When utilizing typical manufacturing, large-scale elements can comprise between 5 to fifty completely different elements, every with a singular provide chain.

These separate parts, produced utilizing casting, waterjet reducing, or machining strategies, should be assembled and individually post-processed. “That offer chain can span 12 to 18 months,” Kreger argued. He highlighted the potential for failure factors and unreliability on this prolonged course of. In distinction, additive manufacturing condenses giant elements right into a single-build course of. This reduces failures and streamlines the provision chain timeline to “4 to 6 weeks.”

Kreger emphasised the flexibleness and cost-efficiency of 3D printing, significantly for low-volume, high-mix manufacturing. He argued that creating a standard provide chain is expensive and solely justifies funding when producing giant volumes. As an alternative, additive manufacturing permits prospects to fabricate smaller runs of distinctive elements at a low price. “That flexibility is one thing prospects actually worth,” added Kreger.

How you can improve 3D printing profitability

The 3D printing trade faces a big profitability problem, particularly amongst {hardware} producers. “Tools producers throughout the board have been fighting profitability,” acknowledged Brad Kreger. He believes that growing adoption is essential to overcoming this.

Kreger means that producers ought to pursue a extra holistic method that’s correctly monetized. This consists of producing peripheral income streams past simply promoting 3D printers.

Velo3D, he defined, had beforehand been laser-focused on techniques gross sales to attain core income. Nonetheless, to enhance the corporate’s prime line and monetary outlook, “we’re now taking a unique perspective and taking a look at companies and help.” This consists of utility help, materials improvement, and repair help.

“The 3D printer isn’t the one element of the enterprise mannequin. Producers must embody the entire set of values and convert that into income,” Kreger added.

Overcoming challenges for flight-ready elements

The Federal Aviation Administration (FAA) continues to be transitioning from machining to 3D printing. This shift, in accordance with Kreger, requires a basic change in how element high quality is assured and controlled.

Conversely, rising operational dangers are accelerating the adoption of additive manufacturing within the protection sector. “The army and authorities are realizing that they should velocity up their efforts to be correctly geared up,” defined Kreger.

Certainly, 3D printing is more and more used to handle shortages of important protection tools. The US army is witnessing a excessive demand for missiles and a scarcity of home suppliers. To deal with this, the US Navy has contracted Ursa Main to design, manufacture and hot-fire take a look at 3D printed stable rocket motors (SRMs) to energy its SM-2, SM-3, and SM-6 missiles.

In accordance with Kreger, growing adoption in protection will increase confidence in civilian purposes. 3D printing for army plane will present a “wealth of knowledge and a physique of proof” that can be utilized to ease aviation and aerospace regulatory challenges.

Safety is a paramount concern when producing elements for protection purposes. Kreger factors to the stringent cybersecurity requirements demanded by the US Division of Protection (DoD), significantly Safety Technical Implementation Information (STIG) compliance.

In accordance with Kreger, Velo3D is uniquely positioned to fulfill these necessities. “We’re the one producer that has STIG compliance and what they name the inexperienced standing,” he acknowledged.

This ensures that delicate file knowledge isn’t externally accessible or residually out there as soon as the half has been accomplished. “Knowledge safety is completely important in defence, and we’ve made a selected trade funding to supply that resolution,” Kreger added.

Register now for AMAA 2024 to listen to insights from trade consultants on additive manufacturing in aerospace, area, and protection.

Wish to assist choose the winners of the 2024 3D Printing Business Awards? Be a part of the Skilled Committee right now.

What does the way forward for 3D printing maintain?

What near-term 3D printing developments have been highlighted by trade consultants?

Subscribe to the 3D Printing Business publication to maintain updated with the newest 3D printing information.

You too can comply with us on Twitter, like our Fb web page, and subscribe to the 3D Printing Business Youtube channel to entry extra unique content material.

Featured picture exhibits a Velo3D-3D printed turbine engine blade disk. Picture by 3D Printing Business.

![[INTERVIEW] RAPID + TCT 2024: Reworking Aerospace, House and Protection with Velo3D’s large-format metallic 3D printing [INTERVIEW] RAPID + TCT 2024: Reworking Aerospace, House and Protection with Velo3D’s large-format metallic 3D printing](https://3dprintingindustry.com/wp-content/uploads/2024/07/Velo3D-3D-printed-turbine-engine-blade-disk.-Photo-by-3D-Printing-Industry-scaled.jpg)