British aerospace agency BAE Programs is producing a supersonic demonstrator to assist the International Fight Air Programme (GCAP).

The piloted plane prototype can be used to check a slew of latest applied sciences, together with stealth-compatible options. Set to be the primary UK fight air demonstrator in 40 years, these exams will assist the event of the Tempest next-generation fighter jet.

Initiated in 2022, GCAP has mixed Japan’s F-X program with the UK and Italy’s Group Tempest venture. It’s working to supply a sixth-generation supersonic fight plane by 2035. BAE is main the venture alongside Italian protection contractor Leonardo, and Japanese producer Mitsubishi Heavy Industries.

The British protection agency is leveraging additive manufacturing to supply main structural parts for the demonstrator, most of that are being made within the UK. In accordance with Paul Wilde, head of Tempest at BAE Programs, “There are elements on the plane that you simply canʼt make in different methods now than utilizing additive processes.”

3D printing was already understood to be enjoying a key function in creating and manufacturing the Tempest plane. BAE beforehand claimed that 30% of the Tempest’s elements can be 3D printed.

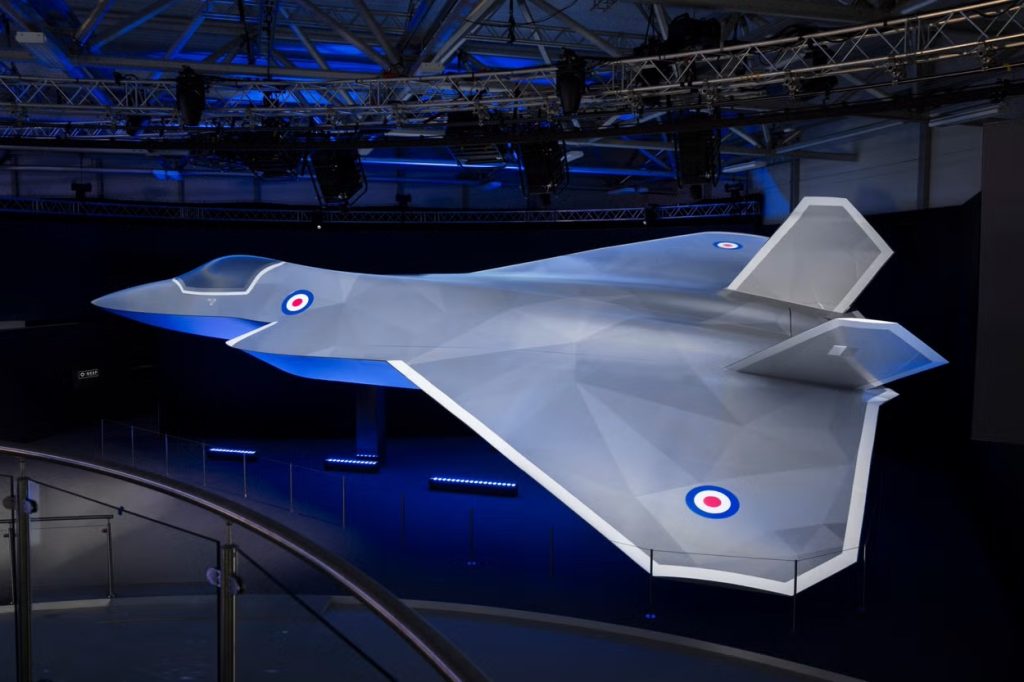

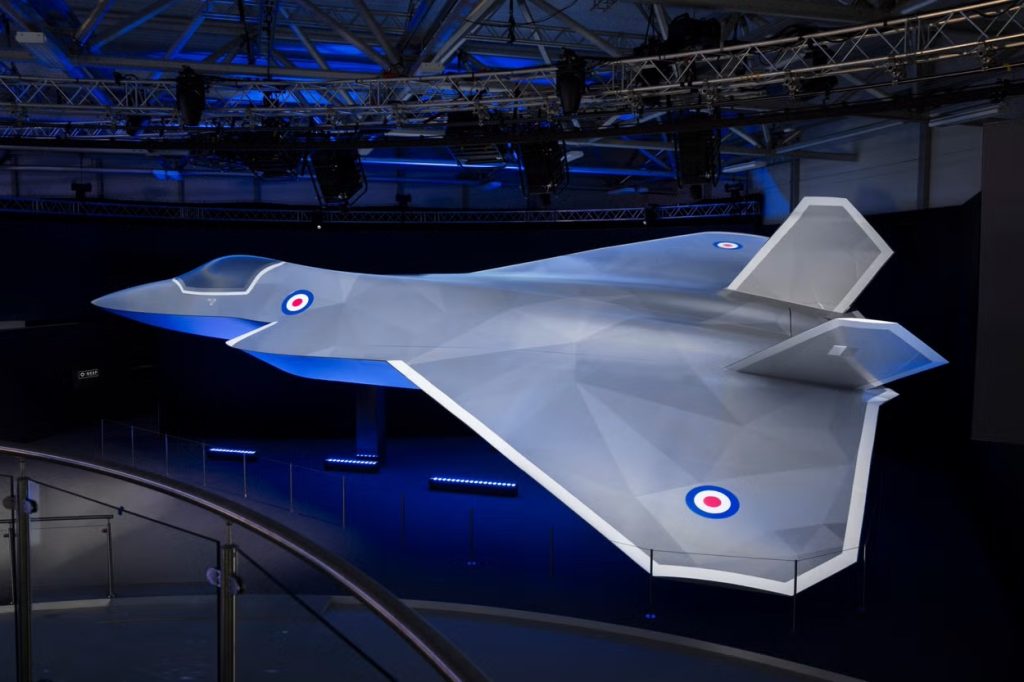

The corporate has additionally unveiled the newest design of the GCAP fighter plane, showcasing a life-sized Tempest reproduction on the Farnborough Worldwide Air Present this week. The mannequin incorporates new design options, together with a bigger wingspan than earlier ideas. This can reportedly enhance the plane’s aerodynamics.

BAE 3D printing a sixth-generation fighter jet

BAE officers have reported that the demonstrator handed a vital design assessment (CDR) in Could. Half the plane prototype’s weight has now been manufactured or assembled, with the entrance heart, rear and wing sections being constructed.

Structural elements are being produced utilizing additive manufacturing processes, together with industrial 3D printing and Scorching Isostatic Press (HIP).

HIP presses powdered titanium collectively beneath intense warmth and strain to supply metallic elements. This minimizes waste and considerably reduces the lead occasions related to forgings. In accordance with BAE, venture engineers have additionally leveraged design for additive manufacturing (DfAM) when producing structural elements.

The time financial savings enabled by additive manufacturing will doubtless play a key function in reaching the brief improvement time of the Tempest. The plane is ready to be delivered simply 12 years after signing the trilateral settlement. That is roughly half the time it took to supply the previous-generation Eurofighter Hurricane.

In accordance with a report from the Monetary Occasions, BAE is 3D printing molds that can be used to fabricate carbon fiber parts for the Tempest. These “mildew instruments” are historically produced from metal, typically taking 26 weeks to supply with typical manufacturing strategies. Utilizing additive manufacturing, BAE can fabricate an entire software in simply three weeks.

By creating the Tempest, GCAP is searching for to supply some of the superior, interoperable, adaptable and linked fighter jets on the planet. It’s set to include an clever weapons system, a software-driven interactive cockpit, and built-in sensors. Subsequent-generation radar will reportedly present 10,000 occasions extra information than present programs.

In accordance with BAE, the Tempest can even turn out to be the primary UK-made tactical fight plane to characteristic an “built-in payload bay” for the reason that Blackburn Buccaneer in 1958. Moreover, the supersonic fighter jet is predicted to be the primary flying platform with a Pyramid avionic design structure, rising its adaptability.

BAE’s demonstrator will present proof for the vital applied sciences, strategies and instruments to be integrated into the long run fight air system.

In Warton, Lancashire, check pilots from BAE Programs, Rolls-Royce, and the Royal Air Drive (RAF) have already spent over 215 hours within the demonstrator’s flight simulator. Whereas the Tempest demonstrator is a UK sovereign effort, the teachings discovered can be fed again into the tri-national GCAP program.

Japan has already flown its future fighter demonstrator, the Mitsubishi X-2, which took to the air again in 2016. Underneath present plans, BAE’s demonstrator is predicted to fly inside the subsequent three years.

3D printing-enabled fighter jets

By adopting additive manufacturing for fighter jet manufacturing, Western nations are searching for to achieve an edge in an more and more fraught geopolitical atmosphere. Nonetheless, Russia and China have additionally adopted 3D printing to spice up their navy plane manufacturing capabilities.

The Russian navy has beforehand used 3D printing to improve MiG-31 jets. Carried out by UEC-Perm Motors and UEC-Star, an affiliate of the state-owned Rostec conglomerate, the upgrades considerably enhanced the interceptor plane’s engine efficiency.

Engineers at UEC-Perm Motors and UEC-Star reportedly 3D printed elements of the MiG’s D-30F6 engine, permitting it to carry out at a ‘new qualitative stage.’ Extra R&D reportedly allow the manufacturing of ‘native engines’ that ship ‘a lot better efficiency.’ Previous to this, Rostec gained a license from the Russian Ministry of Business and Commerce to serially 3D print aerospace elements. This adopted a profitable state-backed check of an additive-manufactured plane engine.

Elsewhere, it has been reported that China’s Shenyang Plane Firm (SAC) has extensively used 3D printing in fighter jet manufacturing. Additive manufacturing know-how is known to have enabled lighter, extra sturdy plane half assemblies.

In 2022, Physician Li Xiaodan of Shenyang Plane Firm’s craft analysis institute informed China Central Tv (CCTV) that “3D printed elements had been broadly used on a newly-developed plane that has made its maiden flight not way back.” He added that “We’re making use of 3D printing applied sciences on plane on a big scale at an engineering stage, and we’re in a world-leading place.”

Wish to assist choose the winners of the 2024 3D Printing Business Awards? Be part of the Professional Committee as we speak.

What does the way forward for 3D printing maintain?

What near-term 3D printing developments have been highlighted by business consultants?

Subscribe to the 3D Printing Business e-newsletter to maintain updated with the newest 3D printing information.

It’s also possible to observe us on Twitter, like our Fb web page, and subscribe to the 3D Printing Business Youtube channel to entry extra unique content material.

Featured picture exhibits the BAE Programs Tempest mannequin on the Farnborough Worldwide Air Present. Photograph by way of BAE Programs.