Absolute EMS, an electronics contract producer, has partnered with Ventiva, a number one firm in energetic cooling options for digital units, to construct their revolutionary Ionic Cooling Engine (ICE). ICE is a cutting-edge cooling know-how that guarantees to redefine thermal administration in electronics. This collaboration highlights Absolute EMS’s capabilities in precision manufacturing and their dedication to offering distinctive customer support, whereas showcasing Ventiva’s modern know-how.

Established in 1996 and headquartered in Santa Clara, CA, Absolute EMS has constructed a repute as a trusted supplier of turnkey contract manufacturing providers. Specializing in all the lifecycle of product growth—from New Product Introduction (NPI) to end-of-life—Absolute EMS ensures the best high quality and precision in each product. Their state-of-the-art facility provides touchless manufacturing, automated first article inspection, and in-line inspection capabilities equivalent to 3D Solder Paste Inspection, (SPI), AOI and X-ray know-how, upholding stringent requirements of excellence. “The product that Ventiva is bringing to market is a modern product that can change the trade,” said Doug Dow, COO at Absolute EMS. “We’re proud to create high tier manufacturing processes to help their success. Our dedication to our buyer relationships, excellence and innovation allows us to satisfy the rigorous calls for of this superior know-how.”

Absolute EMS’s certifications, together with ISO 13485:2016, AS9100 Rev D, and ISO 9001:2015, display their dedication to excessive reliability manufacturing. Their experience spans numerous industries equivalent to medical, navy, industrial, networking, and engineering, offering custom-made high quality reporting, gadget historical past file retaining, and traceability to the element degree.

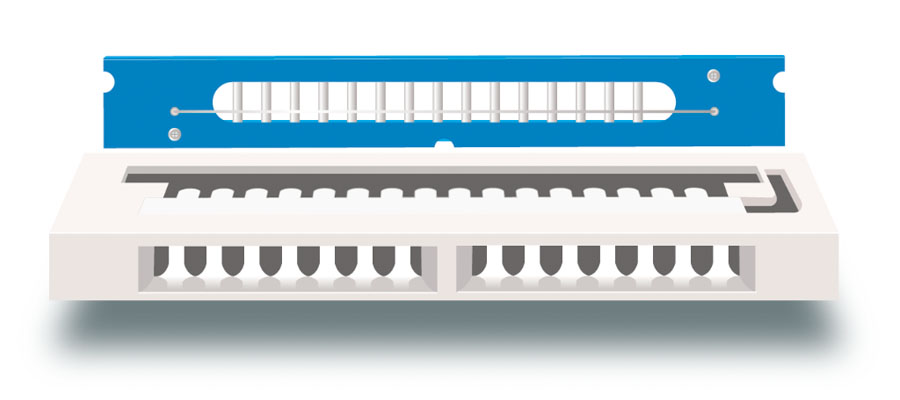

Ventiva, primarily based in Silicon Valley, is thought for its groundbreaking Ionic Cooling Engine (ICE®) know-how. Developed over a 12-year interval, ICE represents a quantum leap in thermal administration by transferring air with out transferring elements, noise, or vibration. Using electrohydrodynamic (EHD) move, ICE generates a potent “solid-state” cooling power appropriate for as much as 30-Watts Thermal Design Energy (TDP) techniques.

“Our know-how addresses the restrictions of standard cooling options in laptops, handheld units and different high-performance electronics. ICE supplies a silent, ultra-compact, and vibration-free various for the AI enabled world,” defined Tim Lester, COO at Ventiva.

The partnership between Absolute EMS and Ventiva is a testomony to the synergy between superior manufacturing capabilities and cutting-edge know-how. Absolute EMS’ position in manufacturing Ventiva’s ICE know-how includes not solely creating the electronics board that powers the gadget but additionally producing the distinctive blower element—a process requiring distinctive precision and adaptability.

“We selected Absolute EMS for his or her flexibility and willingness to assist us in a brand new class the place no person has manufacturing expertise,” added Lester. “Their help has been essential in rushing up our manufacturing iterations and guaranteeing high-quality outputs.”

Because the demand for extra environment friendly, silent, and compact cooling options grows, the collaboration between Absolute EMS and Ventiva is poised to make important impacts within the electronics trade. Ventiva’s ICE know-how is ready to interchange conventional followers in numerous purposes, beginning with laptops and ultimately extending to handheld units, VR headsets, and extra.

“We’re excited in regards to the potential of ICE know-how and the position it is going to play in future digital units,” added Doug Dow. “Our partnership with Ventiva exemplifies our dedication to supporting modern applied sciences and serving to our clients achieve aggressive markets.”

The collaboration between Absolute EMS and Ventiva showcases one of the best of each worlds: superior manufacturing capabilities and groundbreaking thermal administration know-how. Collectively, they’re set to revolutionize the way in which digital units are cooled, paving the way in which for quieter, extra environment friendly, and extra compact electronics.