Throughout RAPID + TCT 2024, Bradley Rothenberg, CEO of Engineering software program developer nTop, outlined how the corporate is driving the adoption of computational design for 3D printing.

North America’s largest commerce present noticed nTop launch nTop 5, the newest model of its flagship design for additive manufacturing (DfAM) software program. Rothenberg outlined a slew of recent integrations with the likes of Materialise and Autodesk’s 3D printing software program.

The right way to use AI for 3D printing was additionally mentioned. Whereas the hype surrounding Synthetic Intelligence (AI) continues to permeate the tech {industry}, the nTop CEO offered a extra pragmatic view of its capabilities. He pointed to the automation of repetitive design duties to save lots of time and minimize iteration cycles from tons of to as few as ten.

Rothenberg highlighted the significance of software program standardization and growing the benefit of 3D printing information switch. He argued this might decrease the barrier to entry and drive 3D printer adoption. Nonetheless, attaining this won’t be simple. The nTop CEO known as information switch “the most important problem for 3D printing software program.”

Learn all of the information from RAPID + TCT 2024

Introducing nTop 5: advancing computational design for 3D printing

nTop 5 is billed as a “leap ahead in computational design know-how.” What’s computational design? In response to Rothenberg, it’s “the method of capturing necessities right into a computer-understandable language like algorithms, after which leveraging compute to run these fashions and discover probably the most optimum design.”

The software program replace reportedly allows customers to “construct, run and combine probably the most highly effective computational fashions into their merchandise.” Rothenberg said, “The {industry} immediately has by no means been below extra strain to ship high-performance merchandise.” He believes nTop 5 is optimized to fulfill these calls for throughout the automotive, aerospace, protection, medical, shopper, and industrial sectors.

nTop’s software program has beforehand been leveraged by Siemens Vitality to transform its fuel turbine engines to hydrogen energy. Cobra Golf additionally used the platform to design the lattice constructions of its 3D printed golf membership irons.

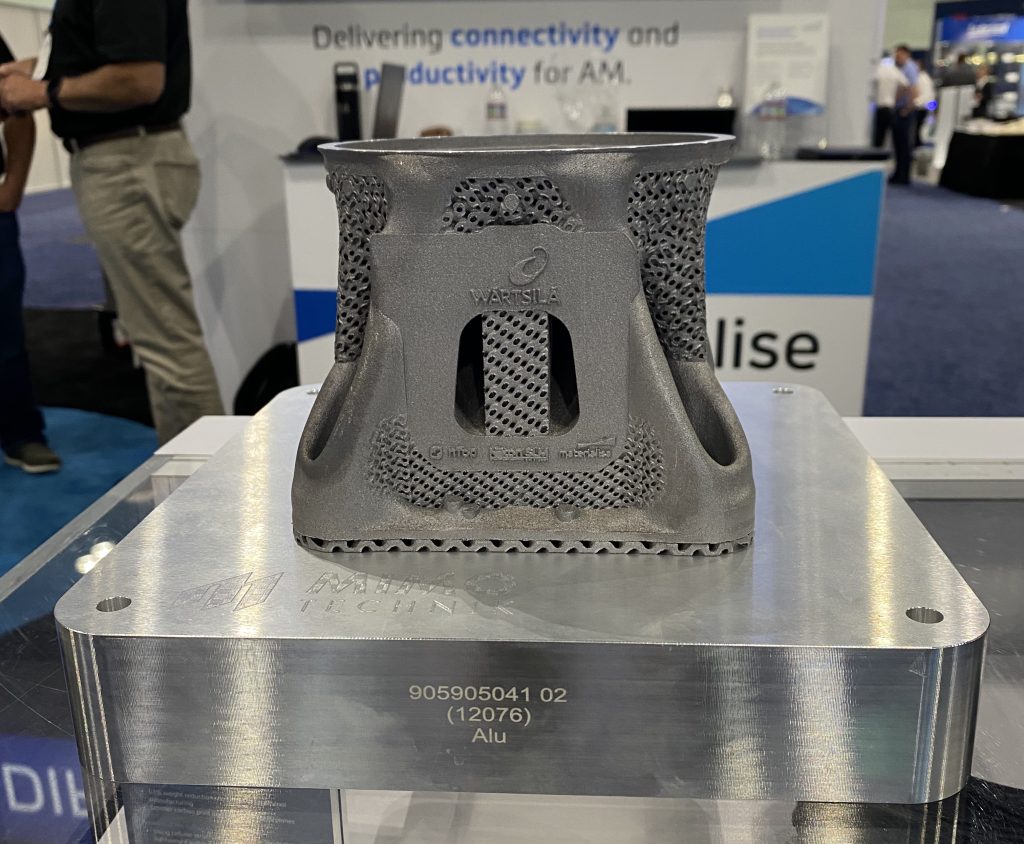

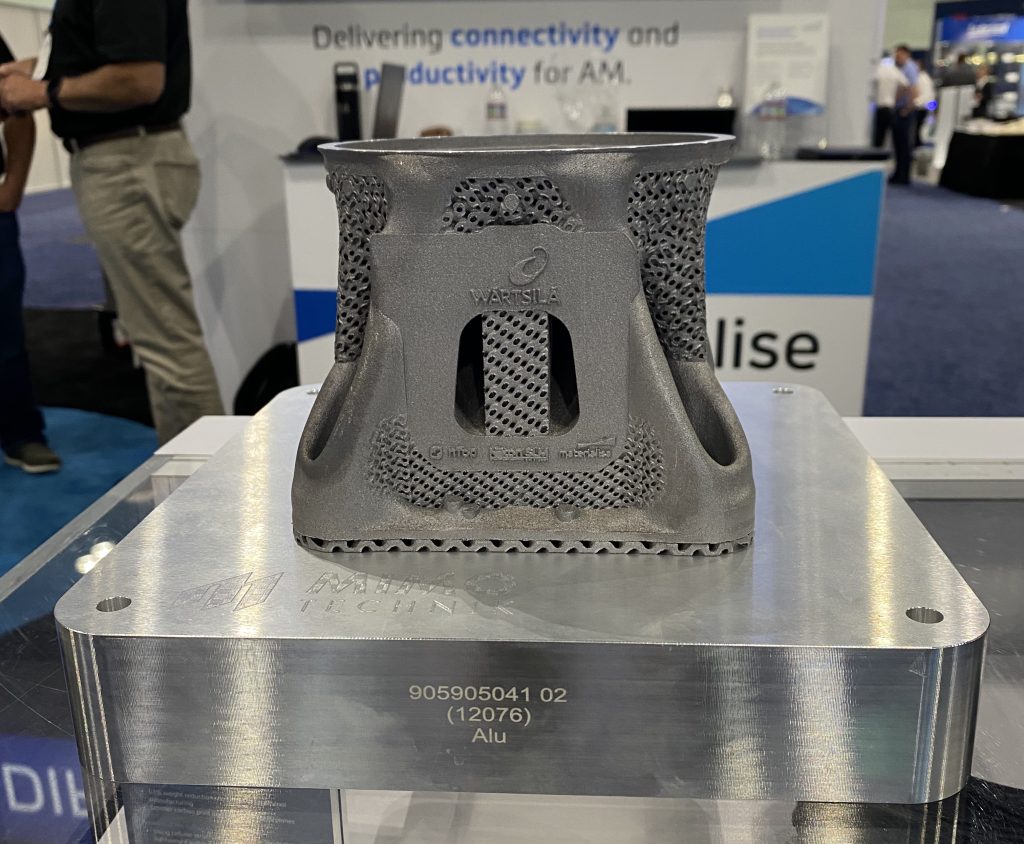

Elsewhere, the corporate’s was used to design a 3D printed cylinder head for the marine and vitality agency Wärtsilä. Developed in collaboration with Materialise and Nikon SLM Options, the half is 60% lighter than conventionally manufactured alternate options. The nTop-enabled design additionally built-in as much as ten subsystems, decreasing meeting complexity and bettering cooling efficiency.

In response to Rothenberg, “nTop 5 marks a extremely necessary second for us.” This is because of new core modeling know-how which affords improved precision and pace. Subsequently, the software program allows prospects to “iterate actually quick and discover the very best design.”

nTop additionally added 5 new software program suppliers to its Core Developer Library. This contains Materialise Magics, Autodesk Fusion, cloudfluid, Hexagon scSTREAM, and Intact.Simulation, which now supply nTop 5 interoperability.

It will reportedly present higher end-to-end design, simulation and manufacturing capabilities for purchasers. Rothenberg believes it will assist to “mature deployment of additive manufacturing and drive extra adoption of computational design.”

How helpful is AI for 3D printing?

Rothenberg shared his insights on the sensible worth of AI and machine studying (ML) in additive manufacturing.

He described AI and ML as instruments that may expedite problem-solving. The instant worth lies in AI’s capability to “pace up related kinds of issues,” offering engineers with quicker, extra correct predictions. “We need to be certain that our prospects practice up customized AI fashions from nTop, and so they might use these fashions to hurry up nTop,” added Rothenberg.

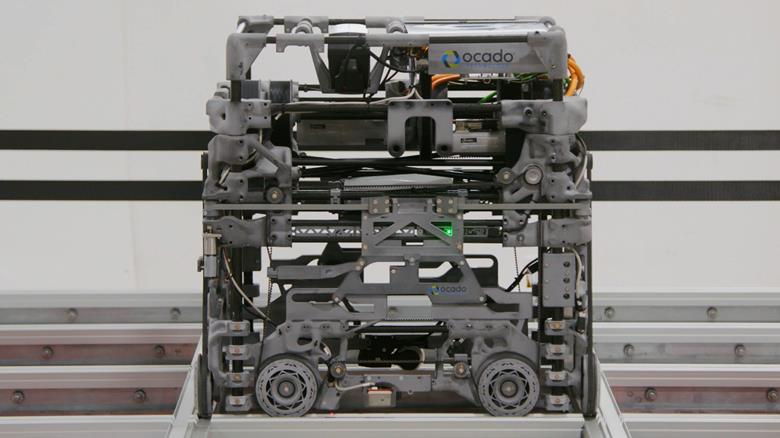

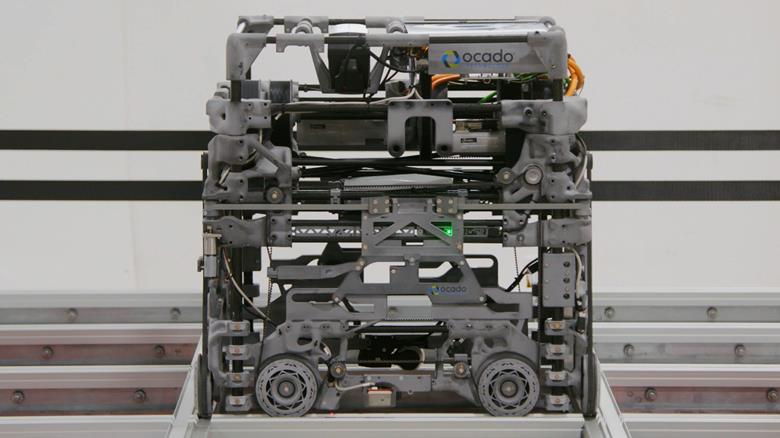

He pointed to purposes like inverse design, the place AI fashions streamline iterative processes. This strategy permits for speedy convergence on optimum designs. One instance pertains to the retail and robotics firm Ocado.

The agency skilled its personal AI mannequin utilizing a digital nTop illustration to hurry up the design of its 600 Collection 3D printed grocery success robotic. This strategy diminished design iteration cycles from tons of to 10 to 50.

Elsewhere, the Lawrence Livermore Nationwide Laboratory has tied an nTop mannequin to conventional AI and ML methods to seek out optimum parameter units for structural design

Nonetheless, Rothenberg defined that AI is “solely nearly as good because the mannequin you practice with it.” Whereas it may well speed up repetitive duties and predict outcomes based mostly on present fashions, AI isn’t poised to invent new options independently.

As a substitute, wanting alongside the engineering toolchain, duties that take hours or days to finish manually may very well be achieved extra effectively with AI-produced surrogate fashions. These duties embody full construct simulations or fluid evaluation, with AI enabling engineers to “get a greater prediction on additive manufacturing outcomes.”

Overcoming 3D printing software program challenges

Rothenberg recognized “clean information switch” between totally different instruments and file codecs as the first problem for the 3D printing software program area. He highlighted the significance of understanding “find out how to transition information.”

To beat 3D printing design bottleneck, nTop affords Implicit Interop. This enables customers to maneuver design information between nTop, manufacturing, CAD, and CAE software program utilizing the corporate’s .implicit file format. It creates recordsdata as much as 99% smaller than conventional meshes, permitting them to be generated 500x quicker.

Rothenberg believes Implicit will change into the industry-standard format for transferring design and simulation information. He added that the latest integration with Materialise’s Magics construct preparation software program helps this objective.

Discussing considerations over mental property (IP) and information safety, the nTop CEO emphasised nTop’s desktop-based capabilities. This enables customers to run software program with out being linked to the cloud, minimizing the danger of undesirable third-party information switch.

Rothenberg additionally talked about ongoing efforts to reinforce file safety, arguing encryption strategies can safeguard shared IP. He outlined measures like Customized Blocks, which package deal IP into nTop recordsdata. The corporate goals to make these recordsdata lockable, with customers requiring a key to entry them after they’ve been shared.

Software program standardization to extend 3D printer adoption

The nTop CEO believes software program standardization will drive 3D printer adoption and scale additive manufacturing to manufacturing purposes.

He defined, “It’s vital that prospects can seamlessly combine designs into their improvement processes.” Rothenberg argued that the integrations launched in nTop 5 handle this want, offering a extra cohesive end-to-end answer for product improvement.

“We view 3D printing as a transformative manufacturing know-how,” Rothenberg commented. Nonetheless, 3D printing’s journey in direction of profitability and widespread acceptance will take time. He likened this course of to the evolution of composites, “which took a long time to achieve mainstream adoption.”

Whereas acknowledging the {industry}’s youth and ongoing monetary uncertainties, Rothenberg is optimistic about its trajectory. He argued for a broader perspective on 3D printing, suggesting it must be thought of a elementary facet of recent manufacturing reasonably than an remoted {industry}.

Register now for AMAA 2024 to listen to insights from {industry} consultants on additive manufacturing in aerospace, area, and protection.

Wish to assist choose the winners of the 2024 3D Printing Business Awards? Be a part of the Skilled Committee immediately.

What does the way forward for 3D printing maintain?

What near-term 3D printing traits have been highlighted by {industry} consultants?

Subscribe to the 3D Printing Business e-newsletter to maintain updated with the newest 3D printing information.

You can even comply with us on Twitter, like our Fb web page, and subscribe to the 3D Printing Business Youtube channel to entry extra unique content material.

Featured picture reveals nTop CEO Bradley Rothenberg at RAPID + TCT 2024. Picture by 3D Printing Business.

![[INTERVIEW] RAPID + TCT 2024: The Worth of AI for 3D Printing, Insights from nTop CEO Bradley Rothenberg [INTERVIEW] RAPID + TCT 2024: The Worth of AI for 3D Printing, Insights from nTop CEO Bradley Rothenberg](https://3dprintingindustry.com/wp-content/uploads/2024/07/nTop-CEO-Bradley-Rothenberg-at-RAPID-TCT-2024.-Photo-by-3D-Printing-Industry-2-scaled.jpeg)