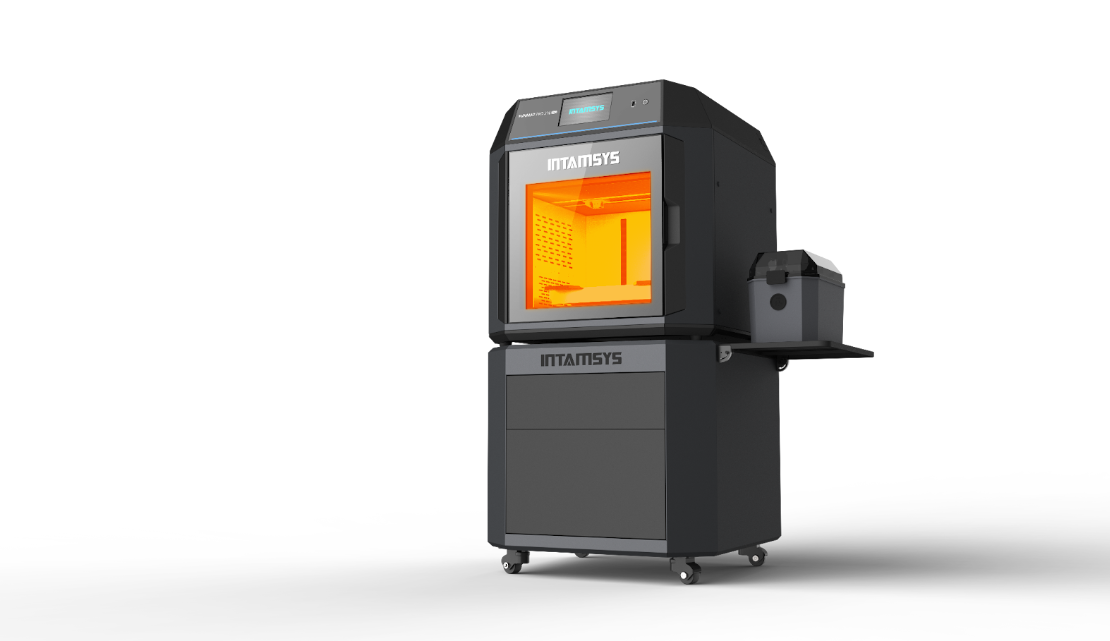

AM options supplier INTAMSYS has introduced the launch of the FUNMAT PRO 310 NEO, a high-speed industrial Fused Filament Fabrication (FFF) 3D printer.

Designed to fulfill the stringent calls for of commercial functions, the FUNMAT PRO 310 NEO presents enhanced precision, materials efficiency, and consistency, making it a super resolution for direct manufacturing and small-batch manufacturing. After 240,000 hours of high-speed manufacturing testing and the profitable printing of over 30,000 elements, INTAMSYS assures dependable, industrial-grade high quality at excessive speeds.

Excessive-speed and high-quality printing for industrial functions

INTAMSYS states that the FUNMAT PRO 310 NEO delivers vital enhancements in manufacturing effectivity, with a median printing velocity of 250mm/s, and a most acceleration of 10,000mm/s². Outfitted with as much as eight materials course of packages supporting supplies comparable to PPA-CF, PC, ABS-HS, and PA12-CF, the printer achieves a manufacturing capability starting from 500g to 1,000g per day.

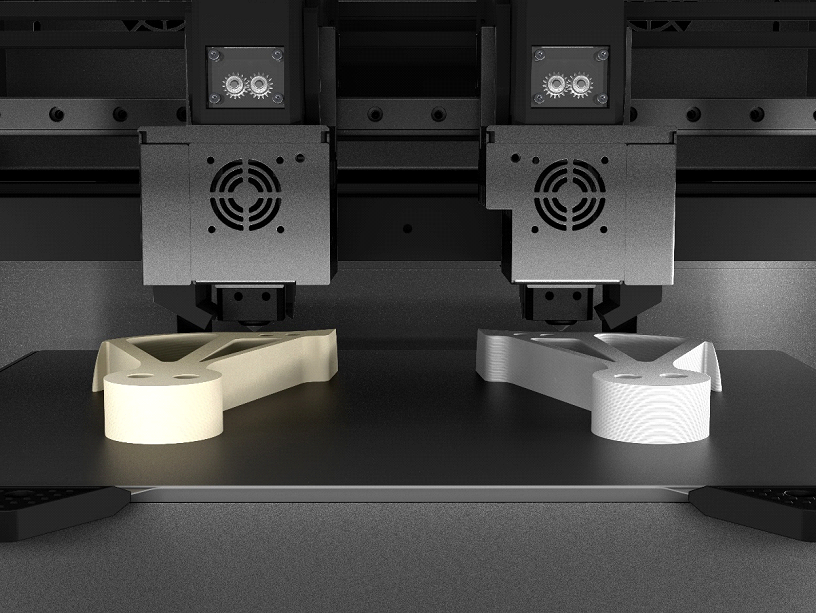

In duplicate and mirror modes, this capability doubles to 1,000g per day. INTAMSYS credit these advances to its newly developed high-speed printing management mainboard and optimized movement management algorithms. The 100°C thermostatic chamber is designed to deal with full-format printing of supplies comparable to engineering plastics, addressing warping and stability points throughout the course of. By conserving temperature fluctuations under 5%, the chamber maintains uniform warmth distribution, which considerably reduces inner stress, deformation, and shrinkage in giant elements.

Excessive and constant temperatures enhance the efficiency of supplies like PC, that are notably inclined to warping. The excessive temperature additionally enhances the mechanical properties of printed elements, particularly supplies like ABS, which present a threefold improve in tensile energy at greater temperatures. This characteristic is essential for making certain the repeatability and consistency of elements, making the printer extremely appropriate for mass manufacturing.

Materials versatility and open-source filament compatibility

With out requiring nozzle modifications, the FUNMAT PRO 310 NEO helps a broad vary of supplies, together with high-performance thermoplastics comparable to PPS, PPS-CF/GF, PPA-CF, and PPA-GF. Moreover, the printer is suitable with open-source filaments, offering customers with cost-effective and versatile selections.

The FUNMAT PRO 310 NEO is suitable with PC-FR, which presents flame-retardant properties for sectors like rail transportation, PC-ABS, ideally suited for long-term out of doors automotive functions, and PC/PBT, which is suited to digital manufacturing. The printer additionally helps versatile supplies like TPU95A. INTAMSYS is constantly increasing its materials portfolio, with new high-speed materials course of packages at present present process testing. Present customers will obtain automated updates and free upgrades as these new packages are launched.

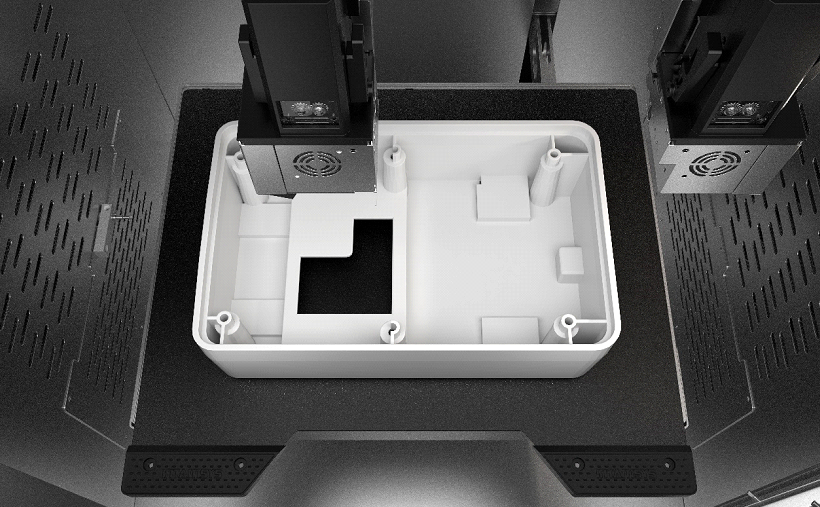

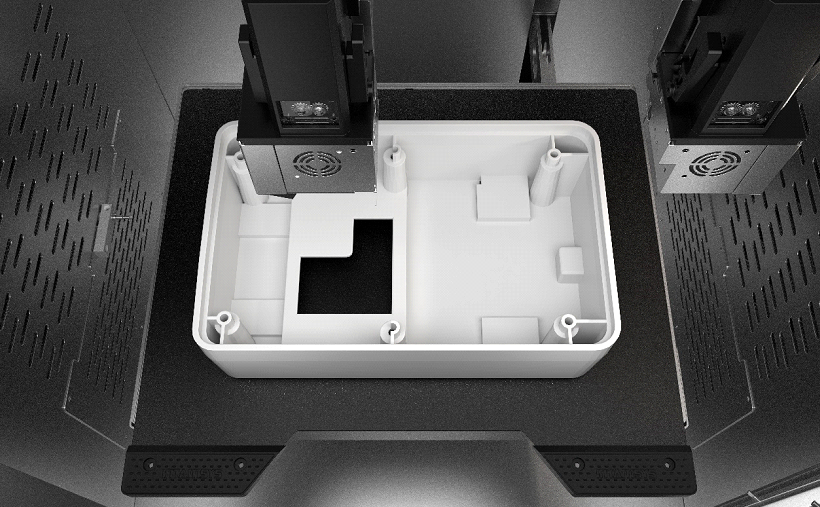

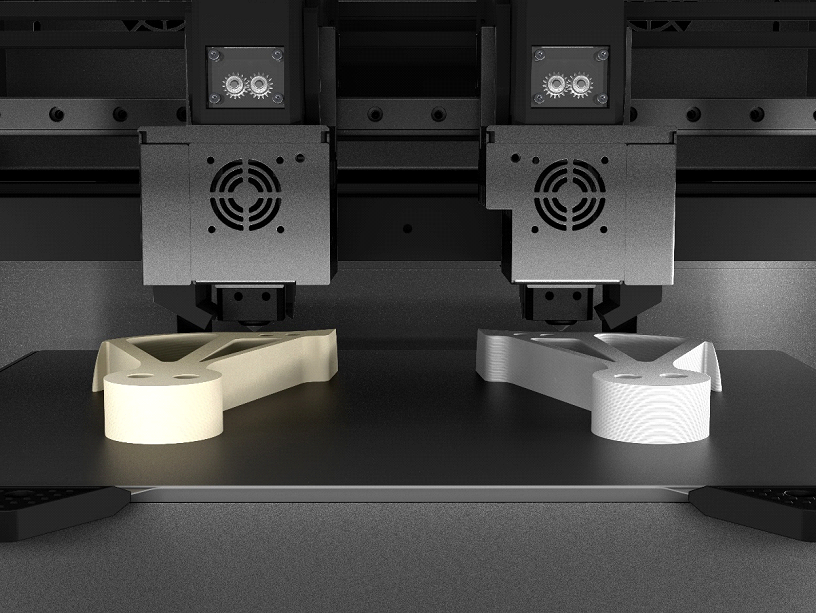

Its Impartial Twin Extruder (IDEX) system additional enhances versatility, supporting 4 printing modes: mirror, duplicate, twin, and assist materials printing. This method permits for high-quality prints of complicated geometries utilizing water-soluble or peelable assist supplies, whereas mirror and duplicate modes improve productiveness.

Enhanced consumer expertise and automation

INTAMSYS has built-in superior options into the FUNMAT PRO 310 NEO to simplify operations and enhance productiveness. The printer consists of IDEX auto Z leveling for seamless calibration and mesh leveling with as much as 10 x 10 modes for real-time accuracy compensation. Distant networking capabilities enable customers to handle process queues mechanically and combine with MES for Business 4.0 compatibility.

Because of the INTAM Field’s sealed design and reusable molecular sieve, humidity is stored at bay, permitting for as much as 20 days of uninterrupted high-quality printing. This characteristic eliminates the frequent drying wanted for filaments susceptible to moisture absorption, comparable to nylon, main to raised print high quality and better effectivity.

Constructed for long-term, steady manufacturing, the FUNMAT PRO 310 NEO offers a quick return on funding (ROI) for each industrial prospects and printing service bureaus. With its sturdy design, the 3D printer operates for prolonged intervals, enabling customers to keep up income streams and improve profitability far past the preliminary outlay.

The FUNMAT PRO 310 NEO’s superior options and flexibility present effectivity and adaptableness for industries aiming to streamline manufacturing and improve half high quality.

Technical specs of FUNMAT PRO 310 NEO 3D printer

| Know-how | FFF (Fused Filament Fabrication) |

| Construct Quantity | Single nozzle: 305 x 260 x 260 mm; Twin nozzle: 260 x 260 x 260 mm |

| Layer Thickness | 0.1 – 0.3 mm |

| Variety of nozzles | 2 (IDEX) |

| Nozzle Temperature | Max. 350°C |

| Printing Velocity | Max. 500 mm/s |

| Printing Acceleration | Max. 10000 mm/s2 |

| Chamber Temperature | Max. 100°C |

| Platform Temperature | Max. 160°C |

| Leveling | Mesh Leveling(Max.100 Factors) |

| Filament Diameter | 1.75 mm |

| Supplies | PC, ABS-HS, PPA-CF/GF, PA, PPS and varied fiber supplies, assist supplies |

| Features | Filament runout warning, distant management, distant printing, on-line replace |

| Voltage | 200 ‒ 240 V/7 A. 50/60 Hz |

| Max. Energy | 1500 W |

| Connectivity | WiFi, Ethernet, USB |

| Display screen | 7-inch contact display screen |

| Construct Plate | Magnetic versatile construct plate |

| Construct Chamber | Absolutely enclosed printing chamber |

| Cooling | Fan |

| Nozzle Upkeep | Fast launch design, simple set up, and disassembly |

| Filament Field | Total sealed field, built-in reusable molecular sieve to maintain dry, temp. and humidity real-time monitoring, standalone |

| Variety of Spools | 2 (Max. 1 Kg/pcs) |

| Decision | XY: 16 μm; Z: 1.25 μm |

| Filtering System | HEPA + Activated Carbon, Replaceable |

| Total Dimensions | 700 x 655 x 700 mm |

| Security Design | Security Door Lock, Over Temperature Safety, Overload Safety, Warning Labels |

| Slicing Software program | INTAMSUITE NEO |

| Supported File Varieties | .stl/.obj/.x3d/.3mf/.stp/.iges |

| Working System | Home windows |

| Working Temperature | 0°C~30°C (32~86 ℉) |

| Working Humidity | 20-70% |

| Storage Temperature | -20°C~55°C (-4~131℉) |

| Storage Humidity | 10-90% |

Nominations for the 2024 3D Printing Business Awards are actually open. Inform us who’s main.

What 3D printing traits do the business leaders anticipate this 12 months?

What does the Way forward for 3D printing maintain for the subsequent 10 years?

To remain updated with the most recent 3D printing information, don’t neglect to subscribe to the 3D Printing Business publication or comply with us on Twitter, or like our web page on Fb.

When you’re right here, why not subscribe to our Youtube channel? That includes dialogue, debriefs, video shorts, and webinar replays.

Featured picture reveals the INTAMSYS FUNMAT PRO 310 NEO 3D printer. Picture by way of INTAMSYS.