Be a part of the Skilled Committee for the 2024 3D Printing Business Awards to assist choose the winners!

Excessive-performance engineering plastics supplier Polyplastics has invested in NematX, an ETH Zurich spin-off, to develop using 3D printed high-performance polymer parts throughout varied industries.

Based on NematX, each R&D groups will collaborate to develop next-generation 3D printing supplies. They are going to synchronize manufacturing processes with the NEX 01 high-precision materials extrusion platform, leading to 3D printed parts with improved precision and sturdy manufacturing capabilities appropriate for industrial manufacturing.

Silvan Gantenbein, CTO and Co-Founding father of NematX mentioned, “Having the ability to develop our long-standing provider and materials growth partnership with Polyplastics as a number one international provider of high-performance plastic supplies is of excessive significance for NematX.”

Excessive-precision 3D printing and sustainable manufacturing

On this joint effort, Polyplastics, with over 60 years of expertise in engineering plastics, will collaborate with NematX’s superior digital manufacturing applied sciences. This alliance seeks to develop progressive, high-quality polymer varieties and bespoke 3D printing methods, assembly stringent high quality requirements for parts in difficult industries.

Furthermore, this collaboration permits NematX to leverage Polyplastics’ in depth expertise with polymers to refine 3D printing decision, warmth resistance, and general materials efficiency. This firm also can additional advance the precision of its 3D printing options and develop its technological capabilities.

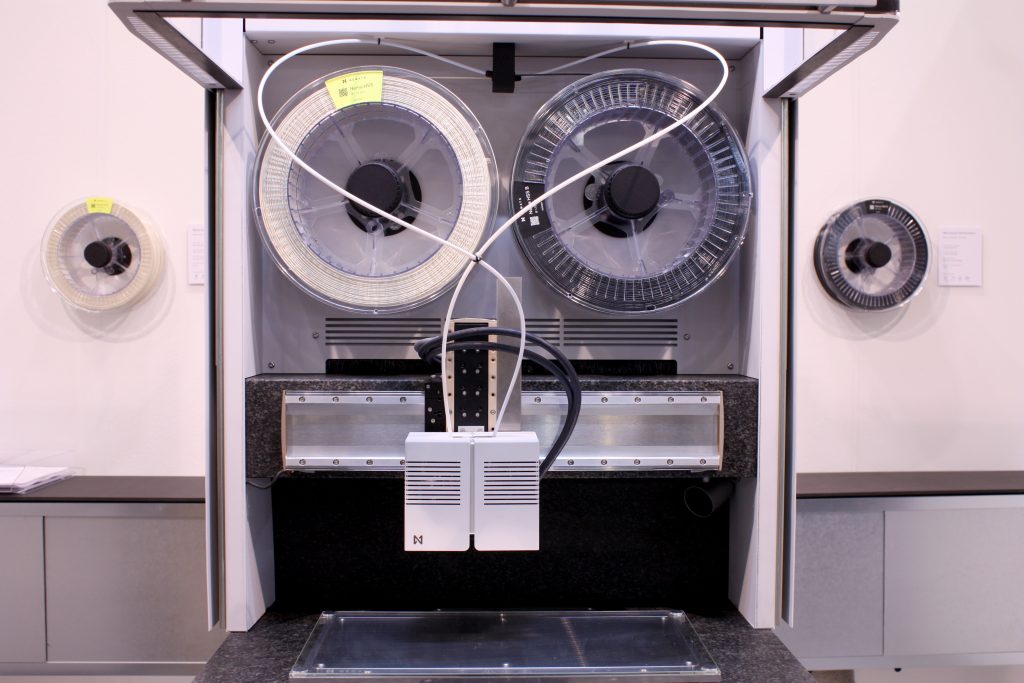

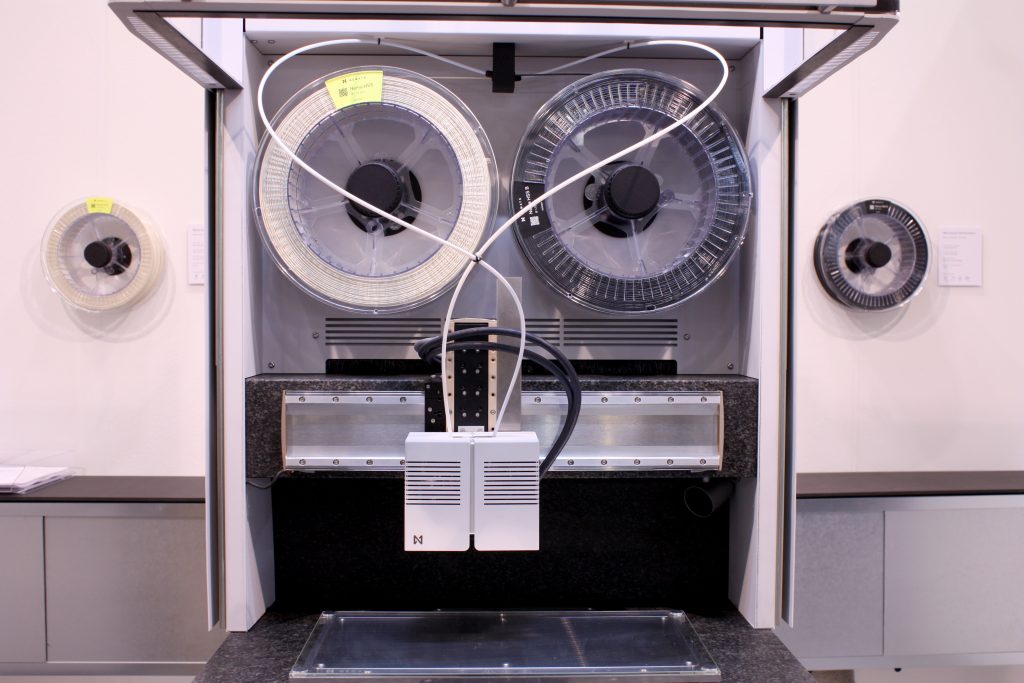

The Swiss-Japanese partnership may even give attention to broadening the worldwide attain of NematX’s NEX 01, a high-precision materials extrusion platform launched in 2020. This printer is designed for high-throughput manufacturing with micron-resolution capabilities. Suitable with Liquid Crystal Polymers (LCPs), the printer permits components with enhanced mechanical, thermal, and chemical properties.

It options superior movement management, fast construct plate alternate, and built-in course of monitoring. NematX’s LCP 3D printing presents options for the semiconductor, mobility, and healthcare sectors, delivering components with high quality corresponding to CNC milling or injection molding. On one other notice, NematX gained trade recognition by profitable the Formnext Begin-up Problem and has since began advertising its LCP filaments.

Moreover, this funding is poised to boost sustainability in manufacturing by fostering the event of eco-friendly supplies and processes, aiming to cut back waste and useful resource consumption.

Developments in polymer 3D printing

Aside from NematX and Polyplastics, different corporations have additionally explored 3D printing with polymers. For example, the POLYLINE undertaking efficiently created an automatic large-scale additive manufacturing line for polymer components.

Accomplished over three years at BMW’s Additive Manufacturing Campus, this undertaking, involving BMW, DyeMansion, EOS, and Grenzebach, sough to advance high-throughput 3D printing for serial manufacturing. Funded by the German Federal Ministry of Training and Analysis with €10.7 million, the undertaking built-in next-generation digitalized manufacturing and highlights the potential for absolutely automated 3D printing factories, as famous by undertaking leaders.

As part of their analysis efforts, Karlsruhe Institute of Expertise (KIT) researchers developed a technique for 3D printing nanoporous polymers with advanced geometries. By combining Digital Gentle Processing (DLP) and polymerization-induced section separation (PIPS), the crew produced buildings from 100 μm to a number of centimeters with managed nanoporosity.

Based on the crew, this system improved adsorption, catalysis, and biomedical purposes. The tactic permits the creation of intricate shapes and will result in developments in light-weight supplies.

Elsewhere, Mosaic Manufacturing introduced the industrial availability of its Array polymer 3D printers, absolutely automated methods for industrial use that includes mattress changeover and AI-powered monitoring. Alongside Array, the corporate additionally introduced the cargo of its Factor and Factor HT 3D printers.

Priced from $79,999, the Array unit consists of 4 Factor or Factor HT methods and goals to boost manufacturing scalability and cut back prices. As well as, Mosaic’s Canvas Edu platform helps instructional establishments with 3D printing administration.

What 3D printing developments do the trade leaders anticipate this yr?

What does the Way forward for 3D printing maintain for the subsequent 10 years?

To remain updated with the most recent 3D printing information, don’t neglect to subscribe to the 3D Printing Business publication or observe us on Twitter, or like our web page on Fb.

Whilst you’re right here, why not subscribe to our Youtube channel? That includes dialogue, debriefs, video shorts, and webinar replays.

Featured picture exhibits the NEMATX crew. Photograph through NematX.